This article was the first serious public look at the technical aspects of and market potential for DVD-Recordable (DVD-R). Some thirteen years later, it’s gratifying to see that DVD-R became, and indeed still remains, a beloved and universal means for enjoying, distributing, storing and archiving just about everything digital.

This article was the first serious public look at the technical aspects of and market potential for DVD-Recordable (DVD-R). Some thirteen years later, it’s gratifying to see that DVD-R became, and indeed still remains, a beloved and universal means for enjoying, distributing, storing and archiving just about everything digital.

In DVD’s Own Image: DVD-Recordable Technology and Promise

Hugh Bennett

EMedia Professional, July 1998

With so much attention being focused on rewritable DVD, potentially the most important of the writable DVD formats has been largely ignored. DVD-Recordable (DVD-R) has started slowly in the market, just as did CD-Recordable (CD-R), but could potentially become the storage and delivery medium of choice for everything from corporate data distribution to home video recording.

Borrowing heavily from many of the technologies used in CD-R, DVD-R is a write-once optical system offering a data capacity of 3.95GB per disc, long media life, and – unlike rewritable cousins DVD-RAM and DVD+RW – physical compatibility with all DVD devices. But with the first available DVD-Recorder (DVR-S101) from Pioneer New Media Technologies costing $17,000 and DVD-R media priced at $50, the initial recordable DVD rollout clearly targets professional markets. Early adopters of the technology are DVD-ROM and DVD-Video developers, who are using DVD-R to create title prototypes, plus controlled applications, such as DVD-based kiosks. General consumer and corporate use of DVD-R, however, will remain a dream until hardware prices fall substantially, disc capacity expands to 4.7GB (promised by the end of 1998), and the installed base of DVD Video and DVD-ROM drives greatly increases.

Borrowing heavily from many of the technologies used in CD-R, DVD-R is a write-once optical system offering a data capacity of 3.95GB per disc, long media life, and – unlike rewritable cousins DVD-RAM and DVD+RW – physical compatibility with all DVD devices. But with the first available DVD-Recorder (DVR-S101) from Pioneer New Media Technologies costing $17,000 and DVD-R media priced at $50, the initial recordable DVD rollout clearly targets professional markets. Early adopters of the technology are DVD-ROM and DVD-Video developers, who are using DVD-R to create title prototypes, plus controlled applications, such as DVD-based kiosks. General consumer and corporate use of DVD-R, however, will remain a dream until hardware prices fall substantially, disc capacity expands to 4.7GB (promised by the end of 1998), and the installed base of DVD Video and DVD-ROM drives greatly increases.

Most industry participants predict that if all of the pieces do fall into place, DVD-R will manifest great market potential by meeting needs not addressed by rewritable DVD formats. Given DVD-R’s write-once nature and inherently low media cost (in volume), similar application uses to CD-R are expected, including premastering, data storage and distribution, archiving, and document imaging. Industry analysts like John Freeman, President of Strategic Marketing Decisions, envision exciting new application areas for consumers where DVD-R “might become part of a home PC entertainment workhorse that lets you put together multimedia videos of your kids and your last vacation and inexpensively send them to grandparents.”

Behind the dream is a blend of old and new technology assembled by the ten companies comprising Working Group 6 (WG-6) of the DVD Forum, namely Pioneer (chair), Eastman Kodak, Sony Corporation, Philips Electronics, Hitachi Maxell, JVC, Matsushita Electric, Mitsubishi Electric, Thomson Multimedia, and Toshiba.

A VISION IN VIOLET: DVD-R DISC CONSTRUCTION

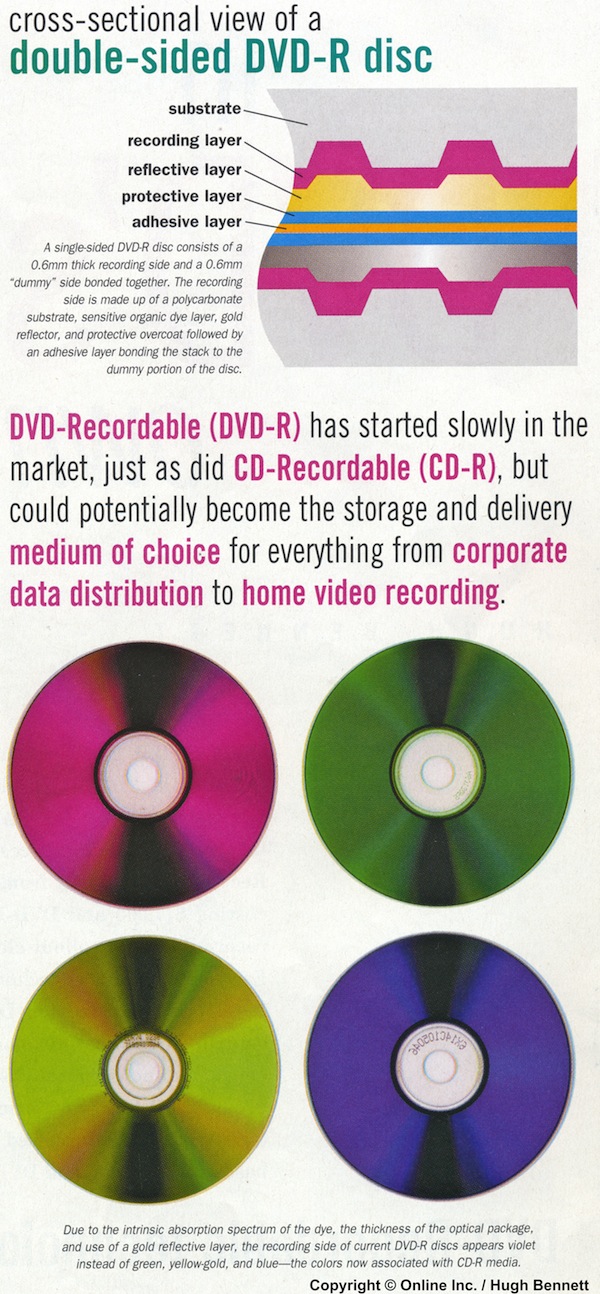

As described in version 1.0 of the DVD-R specification, DVD-R media can take the form of 12cm or 8cm discs in either one layer single- or double-sided configurations. However, it is generally expected that 8cm and double-sided discs will be reserved for more specialized applications.

In terms of construction, a single-sided DVD-R disc consists of a 0.6mm thick recording side and a 0.6mm “dummy” side bonded together to form a single entity. Much like a CD-R disc, the recording side of a conventional DVD-R disc is a tuned optical stack composed of polycarbonate substrate, sensitive organic dye layer, gold reflector and protective overcoat. An adhesive layer bonds the recording stack to the dummy portion of the disc, which typically consists of another polycarbonate substrate, cosmetic aluminum reflective layer, and lacquer overcoat.

Unlike CD-R media, which uses recording layers based on several types of sensitive organic dyes, including cyanine, phthalocyanine, and azo, first-generation DVD-R discs use only formulations of cyanine dye. Due to the intrinsic absorption spectrum of the dye (tuned to absorb light in the range of 635nm instead of 780nm), the thickness of the optical package and use of a gold reflective layer, the recording side of current DVD-R discs appears violet instead of the green, yellow-gold, and blue colors now associated with CD-R media. As the technology matures, the range of recording and reflective materials used in DVD-R will expand and the visual appearance of the media will no doubt evolve.

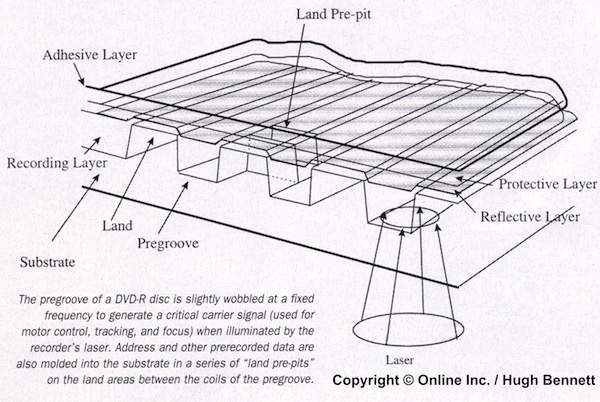

Also, like a CD-R disc, the substrate of a DVD-R disc contains a continuous spiral pregroove that, when viewed from the recording side, extends clockwise from the inside to the outside diameter of the disc. The pregroove is slightly wobbled side to side at a fixed frequency to generate a critical carrier signal (used for motor control, tracking, and focus) when illuminated by the recorder’s laser. However, unlike a CD-R disc which encodes address and other prerecorded data in a frequency modulation of the pregroove carrier signal (Absolute Time In Pregroove or “ATIP”), such information in a DVD-R disc is molded into the substrate in the form of a series of pits and lands (known as land pre-pits) on the land areas between the coils of the pregroove.

Also, like a CD-R disc, the substrate of a DVD-R disc contains a continuous spiral pregroove that, when viewed from the recording side, extends clockwise from the inside to the outside diameter of the disc. The pregroove is slightly wobbled side to side at a fixed frequency to generate a critical carrier signal (used for motor control, tracking, and focus) when illuminated by the recorder’s laser. However, unlike a CD-R disc which encodes address and other prerecorded data in a frequency modulation of the pregroove carrier signal (Absolute Time In Pregroove or “ATIP”), such information in a DVD-R disc is molded into the substrate in the form of a series of pits and lands (known as land pre-pits) on the land areas between the coils of the pregroove.

As the recorder’s laser beam follows the pregroove, the land pre-pits are contacted peripherally and create a second pattern of light reflected back to the photodetector. Since the land pre-pits generate a different signal frequency than the pregroove wobble, the encoded information can be extracted and used. In the case where land pre-pits might occupy positions opposite each other on the same pregroove, conflict is avoided by assigning them offset even and odd positions.

Internal Disc Arrangement

Internally, discs are divided into sections serving distinct functions. Nearest the center hub is the Power Calibration Area (PCA) which is reserved for performing laser power tests before writing. This is followed by the Recording Management Area (RMA) where the recorder retains information for its own use including data obtained during OPC procedures, and recorder and unique disc identifiers for piracy protection. A disc status portion of the RMA section indicates if the disc is empty or how it has been written and information about locations of data if the disc has been recorded incrementally (a capability expected in future DVD-R systems, but not available in Pioneer’s initial model).

After the PCA and RMA is the largest region called the Information Area (consisting of the lead-in, Data Recordable Area, and lead-out) and is the only part of the disc accessible to read-only DVD drives. The lead-in contains data necessary for the disc to be read correctly, including its format, the version of the specification used, physical size and structure, minimum read-out rate, recorded density, as well as pointers to the location of the Data Recordable Area where all of the user data resides. The lead-out then acts as a boundary area so the drive knows when the end of data has been reached.

DVD-R RECORDING PROCESS: EYE OF A NEEDLE

A DVD-Recorder writes data by focusing a pulsing 635nm high power (6-12mw) laser beam in the dye-filled pregroove of the rotating disc. Through exposure to the coherent light, varying lengths of dye are precisely heated and are irreversibly bleached or form permanent features (including partial deformation of the underlying substrate), called “marks,” which simulate the pits of a molded disc. The regions between marks not exposed to the laser pulses are left intact and like their molded counterparts are called “lands.”

Compared to a CD-R disc, the mark and land lengths and track spacing on a DVD-R disc are roughly half the size so accurate writing is a significant challenge. The primary method a recorder uses for creating the correct length marks and lands is by controlling the intensity and duration of laser pulses according to a carefully calculated pattern called a “write strategy.” Unlike CD-R write strategies which are relatively straightforward, those used for DVD-R are significantly more complex. Instead of initiating a write pulse and sustaining it for the time it takes to form the mark, a DVD-Recorder modulates its laser between recording and reading (bias) power repeatedly in a “multi-pulse train” throughout the mark creation process. Since the size of the laser spot used for DVD-R is, proportionally to the marks, much larger than in CD-R, the series of smaller pulses is used to offset the restricted resolution and accumulating heat, both of which can create oversized marks.

Optimal write strategies can vary between different types of media so, in addition to a basic write strategy, the DVD-R specification also allows multiple alternate strategies to be used. As an option, media manufacturers can include in their discs the variables necessary for modifying the recorder’s write strategy in a “write strategy code,” located in the land pre-pits of the lead-in area.

Optimum Power Control (OPC)

The correct amount of laser power needed to write each DVD-R disc varies according to the individual recorder, disc, and environmental writing conditions, so recorders may perform an initial Optimum Power Calibration (OPC) procedure to determine the best writing laser power setting for each disc and recorder combination.

This is accomplished by writing test patterns in the Power Calibration Area (PCA) at different laser powers and reading them back to look for differences (asymmetry or beta) between the lengths of marks and lands. The power setting responsible for the desired amount of beta is then established as the recording power for the disc and all the information acquired during the OPC operation is written for future reference in the disc’s Recording Management Area (RMA).

CD-R was often criticized for the limited space available to conduct OPC operations and for the problems it created for packet writing where discs are consecutively written to at different times. Lessons learned from that experience shaped the design of DVD-R. Not only can a DVD-R disc’s PCA accommodate 7,088 discreet calibrations, the RMA can also retain OPC information for use by as many as four different recorders so as to reduce the number of procedures that need to be performed.

The DVD-R specification also recommends the use of Running Optimum Power Control (Running OPC) to help ensure that the proper recording power is used across the entire disc. Although not implemented by Pioneer’s first-generation DVR-S101 recorder, Running OPC is generally acknowledged as an important hardware feature given the much tighter tolerances resulting from using high numerical aperture optical systems (0.6 NA). As the market matures and new features like incremental writing are introduced, Running OPC’s ability to deal with variations in hardware and media (as well as dust, scratches, and fingerprints on discs) will play a critical role in ensuring data integrity.

Capacity Constraints: 3.95 Isn’t 4.7, but 4.7 Isn’t Either

Due to technological constraints in available media and 635nm lasers, the capacity of a first-generation DVD-R disc is less than that of a molded DVD-ROM. Currently, single-sided 12cm discs hold 3.95GB and 8cm discs hold 1.23GB of data. The difference in capacity between recordable and molded discs results from the use of greater track spacing (0.80µm versus 0.74µm), longer minimum pit (mark) length (0.44µm versus 0.4µm), and faster reference velocity (3.84m/s versus 3.49m/s).

The next version of the DVD-R specification-due by the end of 1998-will make full 4.7GB capacity possible and will be accomplished with new discs using the same reference velocity and track pitch as molded discs which results in smaller marks that are more tightly packed. But like any storage medium, the formatted disc capacity of a DVD-R disc will likely prove to be less than advertised. Taking into consideration lead-in, lead-out, and file system overhead, the available usable space on a 3.95GB DVD-R disc will average 3.6GB, while its “4.7GB” successor will typically offer 4.35GB of usable disc capacity.

CD-R/DVD-ROM/DVD-R Physical Comparison Chart

| CD-R | DVD-ROM | DVD-R | |

| DISC | |||

| Disc diameter | 12 cm, 8 cm | 12 cm, 8 cm | 12 cm, 8 cm |

| Disc thickness | 1.2 mm | 1.2 mm (2 x 0.6 mm) | 1.2 mm (2 x 0.6 mm) |

| Disc structure | Single substrate | Two bonded substrates | Two bonded substrates |

| Track pitch | 1.6 μm | 0.74 μm | 0.80 μm |

| Minimum pit length | 0.83 μm (1.2 m/s) 0.972 μm (1.4 m/s) |

0.4 μm (single layer) 0.44 μm (dual layer) |

0.44 μm |

| Data layers | 1 | 1 or 2 | 1 |

| Max. data capacity | 553 MB (12 cm,1.4 m/s) 650 MB (12 cm, 1.2 m/s) 158 MB (8 cm, 1.4 m/s) 184 MB (8 cm, 1.2 m/s) |

4.7 GB x 2 (12 cm, single layer) 8.54 GB x 2 (12 cm, dual layer) 1.46 GB x 2 (8 cm, single layer) 2.66 GB x 2 (8 cm, dual layer) |

3.95 GB x 2 (12 cm) 1.23 GB x 2 (8 cm) |

| Reflectivity | > 0.65 | 45 to 85% (single layer) 18 to 30% (dual layer) |

45 to 85% |

| Reference velocity | 1.2 to 1.4 m/s | 3.49 m/s (single layer) 3.84 m/s (dual layer) |

3.84 m/s |

| Modulation | 8/14 | 8/16 | 8/16 |

| Track format | Wobbled groove | n/a | Wobbled groove |

| Addressing scheme | ATIP | n/a | Land pre-pit |

| Rotational control | CLV | CLV | CLV |

| READING OPTICAL SYSTEM | |||

| Readout laser wavelength | 770 to 830 nm | 650/635 nm | 650/635 nm |

| Numerical aperture | 0.45 | 0.60 | 0.60 |

| Read laser power | < 0.7 mw | < 1.0 mw | < 1.0 mw |

| RECORDING OPTICAL SYSTEM | |||

| Record laser wavelength | 770 to 830 nm | n/a | 635 nm |

| Numerical aperture | 0.45 | n/a | 0.60 |

| Write laser power | 4-8 mw (1x) 8-10 mw (2x) 10-12 mw (4x) 12-14 mw (6x) 14-18 mw (8x) |

n/a | 6-12 mw |

Recording Speed: Revving Past Real-Time

As demonstrated by CD-R, it’s not just capacity and compatibility that determines an optical format, but also a forward migration path that protects and expands upon customers’ technology investments. This includes read and write compatibility with future generations of hardware, and high-speed reading and recording capability as well. For example, high-speed writing ability has greatly increased CD-R’s overall appeal, value, and application use.

According to the current specification, DVD recording is a 1X or real-time process (1.32MB/sec transfer rate) which means it takes approximately 50 minutes to write a full 3.95GB disc. When 4.7GB hardware and media become available, writing a complete disc will require roughly an hour. In comparison, CD-R discs that once took 72 minutes to record at 1X (0.15MB/sec) now take 9 minutes on today’s fastest 8X (1.17MB/sec) recorders. For CD-R, eight-speed, however, is generally thought to be the practical limit for one-head, single-beam recording.

Similarly, since 2X DVD-Recording is roughly equivalent to 8X CD recording in terms of technological challenge, there are dissenting opinions from inside the DVD Forum that DVD-R, as currently envisioned, will hit a speed barrier that will prevent future growth into critical areas, such as on-demand publishing and duplication applications.

This is due to DVD-R’s reliance on dye-based media which intrinsically have limited sensitivity to light. To overcome their sensitivity problem, complex write strategies are used, but at increasing speeds the strategies become so involved as to exceed the limits of how fast a recorder can accurately pulse its writing laser. Given this foreseeable limitation, some companies are taking a longer term view in their DVD-R media development programs and are exploring alternatives to dyes. For example, according to Dan Kern, Worldwide CD-R Marketing Manger for Eastman Kodak, his company has developed a hybrid material which “offers not only increased sensitivity, but a consistent marking mechanism which lend themselves to high-speed recording.”

Recording Methods and Software: An Incremental Evolution

As with CD-R, controlling a DVD-Recorder requires the use of an intervening program or driver that sequences and converts the files to be written into the correct logical format before writing in either Disc-At-Once (DAO) or incremental fashion.

In DAO recording, the entire disc is written in one continuous operation and no more information can be added after recording is complete. On the other hand, incremental recording allows files to be written as few as one at a time in a manner similar to writing to a floppy or hard drive. The only DVD-Recorder available today, the Pioneer DVR-S101, supports only DAO recording, with incremental capability planned for next-generation products.

In the case of expensive turnkey authoring equipment, the recorder is controlled by the system. However, for more general-purpose data recording there are currently PC and Macintosh DAO software solutions available from Elektroson, Prassi Software, and Adaptec. While features may vary from package to package, common to all is the ability to write discs in UDF version 1.02 (UDF Bridge) format. Since bridge discs contain both UDF and ISO 9660 file systems, broad compatibility is maintained with existing and future operating systems. For example, written discs are readable by current operating systems, such as Windows 95 using ISO 9660 drivers as well as new operating systems, such as Windows 98 and Mac OS 8.1 using UDF 1.02 drivers.

On the other hand, discs written incrementally, unlike their DAO counterparts, are incompatible with existing drivers and hardware. To be read, such discs will require future UDF 1.5 or higher drivers, as well as DVD devices with firmware written to accommodate the special way in which incremental data resides on the disc.

WILL IT PLAY IN PEORIA: DVD-R COMPATIBILITY, INTERCHANGE, AND LONGEVITY

Just as much of the attraction of CD-R comes from its inherently compatible nature, so a primary selling feature of DVD-R is its ability to be read by any DVD device. However, given some of the historical compatibility problems among CD-R media, recorders, and CD-ROM drives, it is reasonable to speculate if the same issues will also affect early generations of DVD-R products. Part of the price to be paid by all DVD formats for their high capacity is reduced manufacturing margins which make interchange and compatibility more susceptible to smaller variations in media, recorders, and drives. Combined with the rush to get products to market some observers privately voice concerns that compatibility issues are inevitable.

The primary method used by the DVD Forum to head off problems before they arrive is by conducting round-robin testing where manufacturers exchange and evaluate other’s products for compatibility with their own. Also seen as critical is continued cooperation by members of industry associations, such as OSTA and the Orange Forum. According to Dr. Jacques Heemskerk, Program Manager for Philips Key Modules Optical Disc Standards, “These organizations made valuable contributions to CD-R and can play a critical role in helping manufacturers participate in DVD verification tasks and by working together to avoid potential issues.”

As some of the primary applications targeted by DVD-R include data storage and archiving, media longevity becomes another significant point of interest. Over the years, tests conducted on CD-R media have led to the generally accepted conclusion that most CD-R discs-properly handled-will survive between 50 and 100 years. Even though DVD-R media lacks a track record or any specific permanence data, expectations are high. According to Tad Ishiguro, General Manager, New Product Planning at Taiyo Yuden, “Given their close relationship, the longevity of DVD-R should be excellent and very similar to CD-R.”

One area of longevity that is still unclear though is how well DVD-R media will stand up to heavy day to day handling. A possible concern relates to the intrinsically weak interface between dye and reflective layers in optical media, such as CD-R and DVD-R. Lacquer overcoats are typically used to protect underlying layers and isolate the interface from any manipulation during handling. But in the case of a DVD-R disc, the bonding of the additional side incorporates the dye/ media interface into the larger structural package of the disc. As a result, delamination becomes possible.

If delamination ever does become a problem, one possible solution may be the use of alternate recording materials. For example, according to Eastman Kodak, the hybrid recording material they have developed forms a stronger interface with metal reflective layers resulting in an intrinsically stronger structure and a more durable disc. In the absence of solid published data, however, it is too early to gauge the longevity and overall durability of DVD-R media. As with any new technology, it is prudent to be alerted to potential concerns and obtain confirmation before entrusting it with critical archival data.

DVD-R ROLLS OUT, ROLLS ON: THE NEXT STEP

Read compatibility with all DVD devices and a disc capacity of 3.95GB make DVD-R currently the only technology which satisfies the professional DVD market’s hunger for project prototyping. But with increasing pressure from rapidly evolving rewritable DVD formats, however, there are differing opinions inside the DVD Forum as to the next step for DVD-R and how to sculpt its specification so as to serve most effectively not just future professionals, but also the potential mass market.

Increasing, the disc capacity to 4.7GB is a given, but rumors abound about political battles being fought over providing greater latitude in write strategies, wavelength ranges, media types, and ways of permitting recordable and rewritable functions to coexist in the same drive-battles potentially divisive enough to fracture second-generation DVD-R into two separate formats. The outcome should be evident by the end of 1998, but as long as the written discs can be read by all DVD devices, does it really matter who sanctions their specification?

A First Look at Pioneer’s DVR-S101 DVD-Recorder

A First Look at Pioneer’s DVR-S101 DVD-Recorder

In contrast to the several manufacturers who have announced either DVD-RAM drives, or at least their intentions to build DVD+RW devices, Pioneer New Media Technologies has the DVD-Recorder market all to itself with its first-generation DVR-S101.

Intended for creating check discs and prototyping DVD titles-to-be, the basic features of the DVR-S101 include 3.95GB capacity, Disc-At-Once recording ability, a 4MB buffer, flash firmware, and single-speed read capabilities. But like any first-to-market product, the DVR-S101 wears a few inevitable shortcomings on its sleeve. Due to the limitations of currently available 635nm lasers, Pioneer expects only about 2,000 operational hours from the DVD-S101’s optical pickup before users will need to replace it. Furthermore, the DVR-S101 requires an environmental temperature of less than 86°F to operate properly, and Pioneer makes it clear that the unit will not be upgradable to support either 4.7GB recording capacity or incremental writing when they become available in the market.

The $16,995 DVR-S101 bundle ships relatively complete with manual, power cord, five blank DVD-R discs and Prassi Software’s DVD Rep recording software for Windows 95 and NT. Unlike first-generation DVD-RAM drives, which are packaged as 5.25″ half-height mechanisms, the DVR-S101 uses a larger desktop form factor (8 9/32″ W x 4 17/32″ H x 16 8/32″ D x 12 lbs.), similar to Pioneer’s CD-R and minichanger products. The unit feels solid and integrates a sturdy tray-loading design with all the comforts of home. Power and tray-eject switches are located on the device’s front bezel along with four status lights. The rear backplane contains two Centronics 50-pin single-ended SCSI connectors as well as SCSI ID and termination select switches.

Realistic system requirements include a Pentium PC running Windows 95 or NT 4.0 with 32MB RAM, CD-ROM drive, bus mastering PCI SCSI adapter, and a 6GB (double if an intermediate image file needs to be created) hard drive capable of sustaining a 1.4MB/sec transfer rate. For this first look, the DVR-S101 was put through its paces using a 200MHz Pentium, Adaptec AHA-2940UW SCSI card, Seagate 6.4GB Ultra ATA hard drive, Windows 95 OSR2 running Prassi’s DVD Rep 1.0 and Elektroson’s GEAR DVD 1.1 premastering software.

During testing, both software packages were used to record full discs containing a cross section of 60,000 very small and large files. Both packages were consistently successful in recording on-the-fly with the assembly and writing process taking roughly an hour to complete. In all, fifteen discs were written, including ten from Pioneer and five engineering samples provided by TDK. To verify data integrity, discs were read back on the Pioneer recorder as well as on Hitachi GD-2000, Matsushita SR-8582, and Pioneer DVD-102 DVD-ROM drives. A byte-level comparison with the source files performed successfully.

THE ONLY GAME IN TOWN

The state of DVD recording is a case of what you see is what you get. Given the current laser limitations, functional gaps, lack of full 4.7GB capacity support, and high hardware and media prices, the DVR-S101 will hardly be mistaken for the people’s DVD-Recorder. However, Pioneer has done a credible job in delivering a first- generation recording system that fulfills an important and immediate need for DVD prototyping and check disc creation.

There is little doubt that a select audience will find the DVR-S101 invaluable, but those looking to DVD-R for data storage, distribution, archiving, and related duties will have to wait for prices to drop and compatibility to flourish with the release of Pioneer’s second-generation, or offerings from other manufacturers, such as Yamaha, Sony, and Philips, who promise recorders sometime in 1999.

DVD-R Recording Software

DVD-R Recording Software

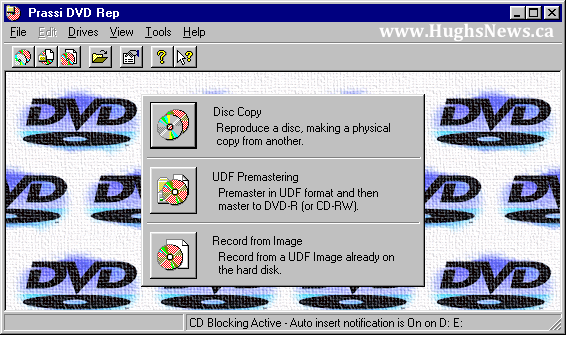

For those not using turnkey DVD authoring systems, several PC and Macintosh data recording software solutions are available to drive the Pioneer DVR-S101, including Elektroson’s GEAR DVD, Prassi Software’s DVD Rep (included with the Pioneer recorder), and Adaptec’s Toast DVD.

GEAR DVD ($2,995) for Windows 95 and NT is essentially a DVD-enabled version of Elektroson’s popular CD recording software and incorporates Software Architects’ file system creation engine for assembling UDF-compliant DVD-ROMs. In addition to physical image or on-the-fly recording using Pioneer’s recorder, the software offers DDP 2.0 support for outputting 3.95GB and 4.7GB images to DLT, Exabyte, and DAT for replication as well as preliminary support for DVD-9 (8.4GB) images for dual-layer DVD-ROM.

Like GEAR DVD, Prassi Software’s DVD Rep also offers UDF premastering capabilities under Windows 95 and NT and records either on-the-fly or physical images as well as a unique copying function for duplicating non-copy-protected DVD-ROM discs.

Given the popularity of the Macintosh as an authoring platform, Adaptec also offers a DVD version of their legendary Toast recording software. Toast DVD (a $99 upgrade from Toast) creates UDF-compliant discs and images including extended attributes (resources forks, window positions, and the like), can overcome the Mac OS 2GB file size limitation by permitting direct output to SCSI hard drives, and is able to record valid DVD Video discs from either supplied images or correct VIDEO_TS directory structures.

DVD-R Disc Duplication with Hoei Sangyo’s DSR-8000

DVD-R Disc Duplication with Hoei Sangyo’s DSR-8000

Unlike early CD recorders, such as Yamaha’s PDS and Sony’s E1/W1 and 900E, which could be chained together in banks to write the same disc simultaneously, Pioneer’s DVR-S101 DVD-Recorder is self-contained and can only record discs one at a time. Hoei Sangyo, long respected for its high-quality standalone CD-R duplication equipment, has extended their expertise into the growing DVD market by offering the world’s first DVD duplicator.

The new DSR-8000 series for DVD uses Hoei Sangyo’s standard PowerBox configuration and supports up to eight Pioneer DVR-S101 DVD-Recorders, a DVD-ROM drive, and an optional hard drive. In standalone mode, the DSR-8000 reads originals through the DVD-ROM drive and can either record on-the-fly or can first generate an image on the optional hard drive for safer recording. The unit can connect to any Mac or Windows host and record a single disc or multiplex output to multiple recorders.

Carrying an anticipated price of around $5,500 for the bare PowerBox controller, the DSR-8000 will undoubtedly appeal to owners of high-end turnkey DVD authoring systems who wish to liberate their host systems when creating multiple discs. Other likely early adopters of the DVD-R duplicator include service bureaus and replicators looking to offer less expensive alternatives to traditional manufacturing for low-run DVD disc production.

DVD-R Media Availability and Pricing

Blank 3.95GB DVD-R discs are available from several sources familiar to CD-R users. Pioneer, TDK Electronics, and Mitsui Toatsu Chemicals manufacture discs and Mitsubishi/Verbatim and Hitachi Maxell also offer Pioneer media rebranded under their own names. Unit prices range from $49 to $80.

Strategic Marketing Decisions’ John Freeman does not see the picture changing any time soon given DVD-R’s current positioning. “3.95GB only serves a small interim professional marketplace wanting to record check discs,” says Freeman, “so media companies can take their time to enter.” Freeman’s sentiments seem to be confirmed in the plans of the leading candidates to manufacture DVD-R media, including the largest CD-R media producer, Eastman Kodak. Kodak’s Dan Kern says, “While we are taking part in the round-robin testing, we are looking forward to 4.7GB and not striving to announce products early.”

The fact that CD-R and DVD-R will coexist for a number of years poses interesting challenges for disc producers according to Brian Bartholomeusz, Vice President of Strategic Business Development for Multi Media Masters & Machinery (4M), a leading provider of manufacturing equipment to the optical disc industry. “DVD-R has more stringent product quality requirements and specialized substrate handling needs that will require significant modifications of existing manufacturing lines,” says Bartholomeusz. Anticipating the need to make both types of discs, 4M offers “a flexible, highly automated, and integrated CD-R/DVD-R manufacturing solution which enables media manufacturers not only to meet the growing demand for CD-R media, but also to position themselves to capitalize on the emerging DVD-R market opportunity.”

With more than 35 companies currently manufacturing CD-R discs, the pool of potential producers for a new media like DVD-R is staggering. In contrast to rewritable DVD media, the inherently low production costs of DVD-R discs could see prices drop significantly in the years ahead.

About the Author

Hugh Bennett, editor-in-chief of Hugh’s News, is president of Forget Me Not Information Systems, a reseller, systems integrator and industry consultant based in London, Ontario, Canada. Hugh is author of The Authoritative Blu-ray Disc (BD) FAQ and The Authoritative HD DVD FAQ, available on Hugh’s News, as well as Understanding Recordable & Rewritable DVD and Understanding CD-R & CD-RW, published by the Optical Storage Technology Association (OSTA).

Copyright © Online Inc. / Hugh Bennett