This article was the first serious public look at the technical aspects of and market potential for CD-ReWritable (CD-RW). Known during its development as CD-Erasable (CD-E), CD-RW is an interesting chapter in the history of optical storage and, fanciful expectations of its promoters aside, continues to endure, long outliving most of its contemporaries.

This article was the first serious public look at the technical aspects of and market potential for CD-ReWritable (CD-RW). Known during its development as CD-Erasable (CD-E), CD-RW is an interesting chapter in the history of optical storage and, fanciful expectations of its promoters aside, continues to endure, long outliving most of its contemporaries.

CD-E: Call It Erasable, Call It Rewritable, But Will It Fly?

Hugh Bennett

CD-ROM Professional, September 1996

Recording has come a long way from the old gramophone through 78s, 45s, and LPs until the market has been overwhelmed by CDs. And modern magnetic tapes, players, and recorders have made storage and reproduction of sound and data available to almost everyone. More recently, the more flush among us could even buy ourselves a CD recorder to make our own CDs. So after half a century of radical change and dramatic evolution, isn’t an inexpensive compact disc that can be recorded over and over again just like those tapes and floppies simply the next logical step?

Well, logical or not, it seems that we soon will be able to take that very step with CD-Erasable (CD-E) technology and a fully rewritable medium that looks like an ordinary, everyday compact disc. The idea of rewritable CD is not new. As far back as 1988, Tandy Corporation claimed that their Magnetic Media Research Center in Santa Clara, California had developed an erasable disc fully playback-compatible with existing CD audio and CD-ROM drives. Dubbed the Tandy High Intensity Optical Recording-Compact Disc (THOR-CD), the new media type was promoted as a technological achievement of biblical proportions. According to Tandy, by 1990 customers would be able to buy erasable THOR-CD consumer audio decks for less than $500, computer storage devices for $1200, and blank discs for no more than $25.

In reality, Tandy’s new disc technology, based on research from Optical Data Inc. of Beaverton, Oregon, was plagued by problems. THOR-CD never saw the light of day due to a combination of media limitations and high hardware manufacturing costs. Labeled “Vapordisc” by the press, it was never heard of again.

But the concept of a rewritable CD did not disappear with THOR-CD. Less than a decade after THOR’s aborted debut, the new CD-Erasable (CD-E) format is poised to enter a far different market than awaited THOR-CD. In the intervening years, the storage world has become far more fragmented and complex with an overabundance of technologies competing for the affections and earnings of increasingly confused purchasers.

Even though CD-E represents a significant technological advancement, simply building it does not ensure an audience that will make it last. A great deal of CD-E’s success will depend more upon nebulous issues like psychological predispositions, timing, and market positioning than on more quantifiable physical factors. Whether CD-E will establish a place for itself in the market, rewrite CD history, or simply become a curiosity remains to be seen, and depends largely upon harder to answer questions of backward compatibility with existing CD formats like CD-ROM, and forward compatibility with the long-anticipated high-density DVD-ROM.

THE NEW CD-E AND ITS IMMINENT MARKET ENTRY

The current technology for a fully rewritable CD system is being introduced by Philips Electronics NV and supported by Hewlett-Packard, IBM, Ricoh, Sony, 3M, Olympus, Mitsubishi Chemical, Matsushita Kotobuki Electric Industries (MKE), and Mitsumi Electric. Offering the promise of a true multifunctional device, the rewritable CD system will be able to read standard CD-ROM, read and write existing CD-Recordable discs, and read, write, and rewrite the new CD-Erasable media. Existing CD-ROM drives, however, will not be able to read the new CD-E discs, but it is expected that this deficiency will soon be overcome with minor modifications made in future drives. Initial pricing of CD-E devices is expected to be in the range of $100 to $200 more than CD recorders; and for the first generation of 650MB (74-minute) rewritable blank discs, costs are projected in the $25 range, with prices possibly falling as sales volumes increase.

When CD-E technology was first announced in April 1995, the companies involved with the new format expected the technical details to be completed rapidly, and consequently, commercial availability of CD-E products was predicted by the fall of that year. Scheduling then changed to spring 1996, and, as that passed, some observers wondered if CD-E could be suffering the same fate as THOR-CD.

According to Cornelius Klick, program director for CD-Rewritable Systems at Philips Electronics, two separate issues have delayed CD-E’s introduction. The first explanation is technical difficulties. Klick says Philips needed “to make sure that not only the hardware, but the software and the media work in a total system and that there could be sufficient compatibility.” Furthermore, for obvious marketing-related reasons, Klick says Philips “didn’t want to introduce it too soon after our CD-Recordable drive [the CDD2000].”

Now, according to Klick, Philips has established October 1, 1996, as the date for the industrial release of CD-E and the start of their hardware mass production. If all proceeds according to plan, Klick anticipates the Philips rewritable CD system to make its market debut at the November 1996 COMDEX exhibition in Las Vegas. Sources closer to the media companies say introduction may be delayed until spring 1997 to ensure that sufficient quantities of CD-E discs are available for sale.

EXISTING CD FORMATS AND THE NEW BOOK ON THE BLOCK

CD-Erasable bears a strong resemblance to other members of the compact disc family. A good way to understand the nature of CD-E (whose recording conditions are articulated in Orange Book Part III) is to compare and contrast its construction and basic principle of operation with that of molded CDs (with physical characteristics established in Red Book) and recordable compact discs (whose recording conditions are described in Orange Book Part II).

Molded Compact Discs: Red Book

Conventional CD-ROMs, like audio compact discs, are made up of three basic layers. The mass of the disc consists of an injection-molded polycarbonate plastic substrate which includes a spiral track of variable-length pits and lands encoding all the data contained in the disc. Over the substrate is a thin aluminum (or gold in premium products) reflective layer, which in turn is covered by an outer protective lacquer coating.

Information is retrieved by a CD-ROM drive focusing a low-powered (0.5mw) infrared (780nm) laser beam onto the spiral track of pits and lands in the disc’s substrate. The height difference between the pits and the adjacent lands creates a phase shift causing destructive interference in the reflected beam. Additionally, the sub-resolved features can induce diffractive light-scattering (analogous to a diffraction grating). These effects modulate from 30 percent to 70 percent the intensity of the light returned to a photodiode detector. The modulated high-frequency signal created is then manipulated, used for tracking, focus, and speed control, and then decoded and translated into usable data.

The gold reflecting layer and dye on the Kodak CD-R disc shown here have been removed, exposing the polycarbonate substrate so the groove and residual dye in the groove from the written mark can be seen. The picture was generated on a Digital Instruments Dimension 3000 Atomic Force Microscope using tapping mode. (Courtesy of G. Lange and S. Chase of the Eastman Kodak Company, Rochester, NY)

CD-Recordable: Orange Book Part II

CD-Recordable discs have a different construction and operate under a different principle than molded CD. CD-R discs use a four-layer system consisting of a polycarbonate substrate, a sensitive organic dye layer, a gold or silver alloy reflector, and a protective lacquer overcoat.

Unlike a conventional CD, the substrate of a CD-R disc does not contain a track of pits and lands. Instead, the substrate contains a slightly wobbled spiral pregroove to provide Absolute Time In Pregroove (ATIP) information. When the disc is rotated at the correct speed under the focused laser beam, the reflected light returned to the photodetector from the pregroove generates a 22.05KHz carrier frequency in the photocurrent providing the critical tracking, motor control, and focus signal for the recorder to stay on course. The carrier is also frequency-modulated (±1Hz) to encode additional data such as time code information, a value for the recommended optimum recording power, and a disc application code.

The most important difference between a CD-R disc and a regular CD is the inclusion of a sensitive dye layer to accept the data to be recorded. Though different dyes are used, such as stabilized cyanine, phthalocyanine-based material, or metalized azo, they are all tuned to absorb light in the range of 780nm.

Rather than having the data molded into the substrate as pits and lands at the factory, data is written to the CD-R disc on demand in a permanent and irreversible way by a CD recorder which employs a higher power laser (single writing speed, 4-8mw; double speed, 8-10mw; quadruple speed, 10-12mw; sextuple speed, 12-14mw) that alters the sensitive dye layer in the pregroove to create areas of decreased “reflectivity.” This is accomplished by the dye’s absorption of the light of the laser beam and converting its energy into heat (250 degrees to 400 degrees Celsius), which alters the dye. Depending upon the dye, some experience a bleaching effect from exposure to the beam while others may create permanent features and some deformation in the underlying substrate.

Instead of employing the physical height change of a molded pit to disperse light, the written marks in the dye mimic the light-scattering effects of molded pits, modulating the intensity of the light beam returned to the photodiode detector, providing a result close enough to a conventional compact disc to be read by Red Book-compliant devices.

Different capacities of CD-R discs are created by rotating at different speeds. An 18- or 63-minute disc (containing 150MB and 540MB respectively) is spun at a real-time Constant Linear Velocity (CLV) of 1.4m/s while 21- or 74-minute discs rotate at a slower 1.2m/s CLV, creating smaller marks and lands and thereby increasing the capacity to 180MB and 650MB, respectively.

CD-Erasable: Orange Book Part III

CD-Erasable: Orange Book Part III

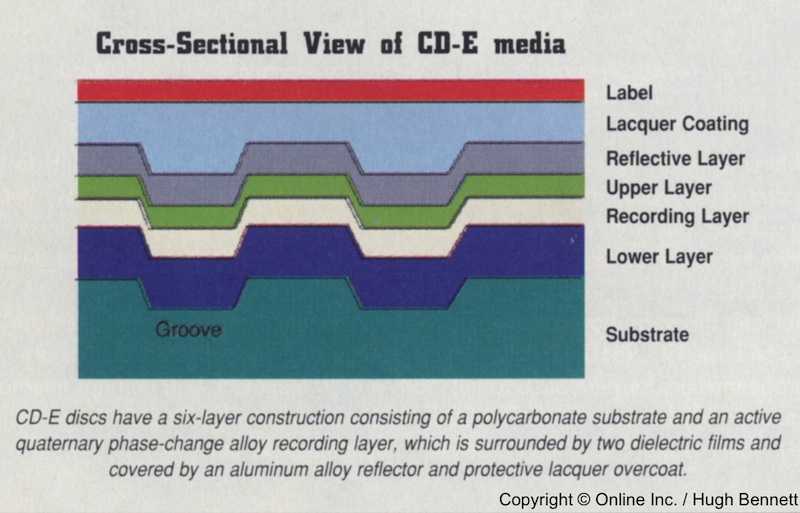

Unlike CD-Recordable, CD-E allows data not only to be written, but rewritten to disc many times over. To accomplish this, CD-Erasable media use a six-layer design consisting of a polycarbonate substrate, a lower dielectric layer, a phase-change alloy recording layer, an upper dielectric layer, an aluminum alloy reflector, and a protective lacquer overcoat.

As with CD-R discs, CD-Erasable media use a polycarbonate substrate into which a spiral pregroove is molded. In addition to the motor control and other information carried in the ATIP of a CD-R disc, a CD-E disc contains information specific to its format, including indicative write power values, recording speed ranges, recommended erase/write power ratios, and other critical data. Like CD-Recordable discs, CD-E media can be rotated at different CLVs.

The real heart of CD-E technology that makes erasability possible is the recording layer. Consisting of a quaternary phase-change alloy composed of silver, indium, antimony, and tellurium, the system operates on the principle of changing the phase of the recording material between a highly reflective crystalline state and a low reflective amorphous state. Unlike other phase-change storage implementations available on the market that “burn bright” or write data by creating areas of increased reflectivity on light-scattering background, CD-E is a “burn dark” system that writes lower reflectivity marks on a reflective surface. This ensures that the resulting track of amorphous marks and crystalline spaces is as optically close as possible to the pattern of pits and lands on a molded CD.

In its deposited state, phase-change material is amorphous, but CD-E media comes from the factory “pre-initialized” to a crystalline state. To write data to a CD-Erasable disc, a powerful (8-14mw) 780nm laser beam is focused in the pregroove and the laser energy is absorbed and heats the crystalline phase-change alloy to its melting point (600 degrees Celsius). When it cools, rather than recrystallizing, it revitrifies into the amorphous state to create the phase change. For rewriting the disc, CD-E is a Direct Overwrite (DOW) system, which means new data is recorded over existing information without first erasing what is already there. To erase/overwrite data, a lower power (4-8mw) laser is focused on the amorphous portions of the recording layer, which raises it to its glass transition temperature (200 degrees Celsius), and it transforms to a crystalline state.

The top pregroove shows the results of initial recording and the lower one has been overwritten in this Transmission Electron Microscope view of the surface of a CD-E disc. Data is written and rewritten by focusing a laser beam in the pregroove to create a pattern of low-reflectivity amorphous marks (appearing in photograph as solid gray areas) and high-reflectivity crystalline spaces.

During recording, the laser power is modulated according to an involved write strategy. Unlike CD-R, where the laser is left at its recording power for the duration of time required to form the desired length of mark, CD-Erasable repeatedly pulses its laser between write or erase power and a very low bias power (≤1mw). The bias power is the same as is used to read the disc. The laser is pulsed to prevent the alloy from accumulating too much heat and creating unsuitably large amorphous marks.

Instead of using the physical height change of a plastic pit to disperse light as occurs with molded CDs, the written amorphous marks in the phase-change imitate the light-scattering effects of molded pits. The change modulates from 15 percent to 25 percent the intensity of the light beam returned to the photodiode detector, and provides a result close enough to a conventional compact disc to be read by Red Book-compliant devices with certain modifications.

Rounding out the erasable disc’s optical stack are two dielectric films, composed of a mixture of silicon, oxygen, zinc, and sulfur. The dielectric layers that surround the recording layer perform four basic functions, as follows:

• modifying the optical response of the media to provide fine signal tuning

• increasing the efficiency of the laser by keeping the heat produced on the recording layer

• acting as a thermal insulator protecting the substrate, pre-grooves, and reflective layers

• serving as a mechanical restraint device to limit the mobility of the recording layer material

In further contrast to CD-R, which can be written at a variety of recording speeds (currently varying from 1X to 6X) by tuning the media and modifying the recorder’s write strategy, CD-E discs are currently optimized for double speed recording (300KB/sec) only. According to Jacques Heemskerk, technical program director for Philips Electronics in Eindhoven, Netherlands, “In Orange Book III we made provisions to extend CD-E to other speeds, but we do not want to initially release write conditions at different speeds before thorough testing. Our priority for 1996 is clear: get CD-E to the market first at 2X and the lowest cost possible.”

READING CD-E

While the read-out signal requirements for a recorded CD-E disc are very close to a standard or recordable compact disc, there are enough differences to prevent backward compatibility with existing CD-ROM drives. Consequently, recorded CD-E discs can only be read using new “CD-E-enabled” players which are essentially modified CD-ROM drives. The only significant differences are in Push Pull (tracking), Rtop and I11/Itop (modulation amplitude) values.

The changes necessary to give standard CD-ROM readers CD-E-reading capability are often characterized in marketing material as being “minor modifications in electronics which all current CD-ROM drive manufacturers can easily implement.” The comparison is made to the minimal modifications needed a few years ago to convert single-session drives to read multisession compact discs, but in practice, the “slight” modifications are potentially more than slight.

For example, to compensate for the substantially lower reflectivity and signal modulation of CD-E than is specified in Red Book, drives must be modified to include Automatic Gain Controls (AGC), which are essentially variable amplifiers. A reader equipped with AGC will detect upon insertion the reflectivity of the disc and boost the gain of the preamplifiers directly after the photodiodes. As an extra precaution, CD-E media carry a special code to identify themselves to the drive as CD-E so as to ensure that the correct range of gain settings are used.

Philips expects that AGC circuitry will be integrated into the next generation of standard chipsets they supply for CD-ROM drives so that when those drives are released, their customers will be able to incorporate the capability for little additional cost. But not every drive manufacturer uses a Philips chipset, so costs for other companies will vary. Additional cost and considerations for drive companies include compatibility testing, firmware modifications to accommodate the AGC, and disc ID and packet-reading capabilities. Depending upon the design, the higher reading power requirements may cause manufacturers to use different laser components, reduce the life of their existing lasers, or add packet-friendly programming not presently included in their products.

Though the technical aspects of CD-E-“enabled” hardware may fall into place by the end of the year, the decision for CD-ROM drive companies to support CD-E is not that simple, and far from a foregone conclusion. Though more CD-ROM drives will be sold over the next four years than are installed today, many drive manufacturers say it is unrealistic to believe that all of them will read CD-E discs and overcome the backward compatibility problem. Given the highly competitive commodity pricing of CD-ROM drives in the marketplace, few drive manufacturers seem enthusiastic about the idea of adding new capabilities to their hardware unless it provides them with the greater product differentiation that will attract more sales.

Philips’ Klick concedes the force of this point. “If it were left purely up to the PC peripheral companies, there would not be a big push to add AGC,” he says. “CD-ROM drive compatibility with CD-E will evolve slower and later and won’t be there from the start.” Klick points out, however, that Philips is “trying to understand the needs of the real users through focus groups, and if the outcome is positive, we will try to have the PC companies specify that the peripheral companies make the necessary changes.” Dave Deane, CD Futures product manager of the Colorado Memory Systems (CMS) division of Hewlett-Packard, confirms they, too, have been actively pursuing this course of action.

Since, according to Klick, CD-E is primarily intended for use in backup applications, users can write CD-R discs on CD-E-capable systems when interchange is desirable. If, however, global CD-ROM drive compatibility with CD-E is not forthcoming, Klick says, “realistically, for that part of the market, I don’t think it will be a problem.” Others, however, disagree.

WRITING CD-E

Many of the issues that face CD-ROM drive manufacturers also face CD recorder manufacturers who must modify their existing drives to work with CD-Erasable. CD-E requires writing laser powers closer to those used in 4X CD recorders, which means that 2X recorder manufacturers may need new laser components. Some existing lasers designed for only two power settings–read and write–will be incapable of reliably generating the three different strengths–read, write, and erase–required by CD-E.

It is expected that Philips and Ricoh will be the first companies offering CD-E recorders on the market. Since Philips sells both components and complete drive assemblies to many other CD recorder manufacturers, such as HP, it is reasonable to assume that many will follow in offering CD-E products. Some analysts say that as the CD recorder market becomes more competitive, some manufacturers will be looking for greater product differentiation and will perhaps look to CD-E to provide it. Philips’ Klick says that Philips’ general view is that “there will be a convergence of the erase function as part of all CD-R drives, maybe in 12 to 18 months. The principal suppliers of CD-Recordable drives will take the migration path from Recordable to Erasable products. We expect they will be showing products at the November 1996 COMDEX,” when Philips’ own rewritable CD system is slated to make its debut.

From the users’ perspective, working with CD-Erasable will involve writing discs in either CD-UDF’s serial or random mode. For those already acquainted with CD-R systems, serial mode will be the most familiar since compatible recording software can write Track-At-Once, Disc-At-Once, packet, or multisession discs. Most likely, however, for most applications, implementations will opt for packet writing. A typical CD-UDF read/write driver makes CD-E discs appear to users like any other storage medium, so files and directories may be dragged and dropped, saved, modified, and deleted in a familiar way, and packets continually appended until the end of the disc is reached. When the disc does become full, a software utility must be run that compresses the data on the disc and recovers all free space from deleted files, a process which under common conditions can take up to five hours to complete.

On the other hand, the random mode works with fixed 32KB packets that can be randomly written and rewritten in a fashion loosely analogous to sectors, with no defragmentation necessary to reclaim free space. The system also has the advantage of disc defect management and sparing for improved data safety. Nothing is for free, so what random packet writing gains in flexibility, it exchanges for reduced performance and a higher overhead, which results in a loss of roughly 120MB of the disc’s capacity.

DVD/CD-E COMPATIBILITY: THE NEXT-GENERATION GAP?

An important consideration for anyone purchasing a new computer data-storage format such as CD-E is the question of generational compatibility. Media is the largest investment users make, so it is important that the next-generation technology be able to read what has already been written.

The question of whether DVD-ROM (the long-awaited high-density computer storage disc) will be backward compatible with any compact disc technology is relatively complex since that compatibility is not part of the DVD specification and therefore not guaranteed. It has been left up to individual DVD-ROM drive manufacturers to decide if their customers want and will pay for backward compatibility. The companies involved in the unified DVD specification have maintained that the specification not stipulate backward compatibility, but that it should be technically conducive to permitting economically attractive backward compatibility for those who choose to offer it.

Regrettably, there are already serious incompatibility issues between CD-R and DVD-ROM, and CD-E represents a third backward compatibility issue. Technically speaking, it is potentially easier to read and write CD-E discs at shorter DVD laser wavelengths than it is to accommodate CD-R media. Unlike the organic dyes used in CD-R discs, phase-change materials such as those used in CD-E are not as wavelength-sensitive and are considerably more panchromatic. [See Hugh Bennett’s guest column, The CD-R Writer, “DVD: A Problem Ignored,” CD-ROM Professional, Volume 9, Number 5, pp. 106-107 –ed.]. Describing Philips’ development efforts on CD-E, technical director Heemskerk says, “It would be nonsense to introduce CD-E media without taking into account how the data would be read back at the shorter wavelength, and Orange Book Part III does include read-out characteristics for CD-E at 650nm.” While some have publicly called CD-E a bridge to DVD-ROM, unless CD-E is taken into consideration during the final tweaking of the DVD specification, it may be technically difficult and cost-prohibitive to provide backward compatibility.

It is, however, probably too soon to determine if DVD-ROM drives will read CD-E. As Philips’ Klick says, “Philips feels backwards compatibility is necessary and a requirement of the data products industry.” Describing Philips’ general DVD-ROM plans, Robert van Eijk, director of CD-Recordable products at Philips Key Modules in San Jose, California, says, “It is our intent to release [hardware] products that are compatible with previous generations.” Whether or not that is possible or economically feasible is another question that only time will answer, but even the expectation offers hope to those who are also concerned about CD-R compatibility with the next-generation DVD-ROM drives.

HOW RELIABLE, REWRITABLE? MEDIA LONGEVITY AND CYCLABILITY ISSUES

The lifespan of any computer storage medium, optical or magnetic, is of great interest, given that critical information is often entrusted to such systems. The traditional environmental enemies of optical media are light, heat, and moisture. For example, in the case of recordable compact discs, excessive light and heat can degrade the disc’s dye layer and reduce the contrast between the pits and lands, making data extraction more difficult. Extreme moisture can potentially oxidize the reflective layer and, in combination with extremely rapid temperature changes, can delaminate the discs. However, generally speaking, CD-ROM and CD-R media can take a fair amount of punishment and, if used and stored reasonably, have the potential to last 50 to 100 years.

Although CD-E is a new system, it is derived from compact disc and phase-change technologies that have been available and used in other purposes for many years and that are consequently fairly well understood. For instance, Ricoh officials declined to provide specific longevity data but did express satisfaction with their accelerated age testing and estimate conservatively the lifespan of CD-E discs as being well over 20 years. Phase-change materials tend to be very stable, so in the absence of evidence to the contrary, there is no real reason to doubt the company’s claims.

Another important consideration in the lifespan of rewritable media is cyclability, which is a key element in determining how many times a disc can be rewritten. Historically speaking, phase-change discs have had limited cyclability and, as a result, have not been used as much as other technologies for storage applications involving the need to write and rewrite data many times over. Cyclability essentially refers to the number of times the phase-change recording material can be reliably switched between its crystalline and amorphous states. CD-E’s recording layer is composed of an alloy of four materials that cleanly transform between an ordered crystalline and a disordered amorphous molecular structure through different amounts of heating and cooling. However, there is a chemical tendency of such alloys to separate and aggregate, so over repeated switches of the material between its orderly and disorderly states, the recording material’s characteristics may change and cease to be dependable for achieving the necessary two well-defined states required for rewritability. As a result, this can lead to elevations in noise so that it becomes difficult for the drive to distinguish between intentional marks and inconsistencies in the recording layer. Similarly, the changes in the alloy’s stability affect the way in which it reacts to laser energy so that marks can no longer be dependably written.

At the time of the original CD-E announcement, Ricoh indicated that the cyclability of the media would be roughly 1,000 times. Further refinements have been made since then, according to Philips’ Klick, who reports that the company expects that when CD-E comes to market, the actual value will be “closer to 100,000 cycles” with a very strong potential for further increases in the future. The issue of cyclability may not be crucial for other reasons too, such as the anticipated applications for CD-Erasable, expected capabilities of the final CD-E media, and logical techniques such as defective area mapping. As Philips’ van Eijk says, “We believe that cyclability is not, in the long run, any factor at all.”

HANDLE WITH CARE: INCREASING THE ODDS FOR SUCCESSFUL REWRITES

The question of how many times or how long you can rewrite data to CD-E media goes well beyond the topic of cyclability. Most optical storage media designed for continual rewriting, such as magneto-optical and phase-change, are sealed in rigid protective jackets and only have their surfaces exposed when their shutter retracts after being inserted into a drive. By contrast, CD-Erasable discs are open to the air like regular CDs and are therefore susceptible to dust, scratches, fingerprints, and other grime before and after writing–all factors that can adversely affect data integrity.

The process of reading data is far more tolerant of discs with surface damage and contamination than is the process of writing data, in large part because features such as embedded error correction schemes and CD-ROM drives that can slow the discs’ rotation to compensate for aberrations of the discs’ surface are built into the read process. By contrast, the computer system only has one brief attempt at writing data. Two significant ways of making the process of writing CD-E discs more tolerant of surface aberrations is by creating a disc with a sufficiently large power window and by using a Running OPC (Optimum Power Calibration) writing technique.

Power window refers to the range of laser energy that will properly form the correct size marks on a disc. For example, a CD-Recordable disc written at double speed might have a power window of 2mw between the range of 8 and 10mw. If the disc is written within this range, the marks formed will be of the proper size. Too much power will create oversized marks and too little power will produce undersized marks.

Scratches, dust, and fingerprints obscure the laser light’s path to the recording layer of the disc, which reduces the laser’s effective power and results in imprecise marks. However, the larger the disc’s power window, the more tolerant it is of these sorts of problems since correct marks can be formed with a greater range of laser energy. In comparison to CD-R, CD-E discs have a significantly larger power window, perhaps aided by the AGC capabilities of the reading drives.

The other method of improving the reliability of the writing process is for the recording hardware to implement a Running OPC system. Running OPC establishes the correct power to record the disc when it is inserted, actively monitors the writing process, and compensates for any abnormalities, such as scratches or fingerprints, by adjusting the laser’s power to record “through” the obstacles. If unsuccessful, the system issues an “absorption control error” and alerts users that there may be a problem with the integrity of the written data. Philips’ Heemskerk says that the company’s forthcoming hardware will implement Running OPC for CD-E.

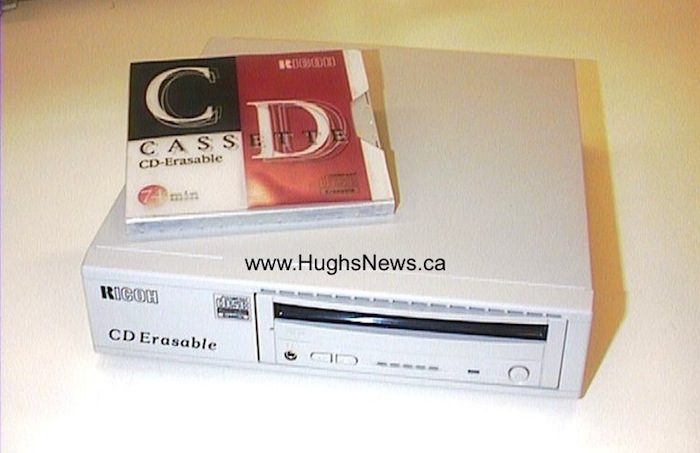

To minimize handling and contamination-induced damage, Ricoh says that they will sell discs preloaded in caddies, a combination they call a "CD-Cassette." According to the company, by minimizing environmental and direct human contact with the discs, dust scratches and fingerprints can be prevented.

To minimize handling and contamination-induced damage, Ricoh says that they will sell discs preloaded in caddies, a combination they call a “CD-Cassette.” According to the company, by minimizing environmental and direct human contact with the discs, dust scratches and fingerprints can be prevented.

Though Ricoh plans to offer a caddy-based CD-E drive, not everyone agrees it is necessary or desirable in the marketplace. There has been a steady move away from caddies to tray-loading CD recorders and CD-ROM drives without reliability complaints, and the trend seems to meet with the approval of the buying public. Philips’ Heemskerk notes that “when CD-ROM was introduced, it was taken for granted that CD-ROM had to be in a caddy, and there was no way to sell a data technology without a caddy”–but that is not the case today. He feels that they “should not re-introduce the cartridge,” since it is no longer what is expected or desired by users. In terms of reliability, Heemskerk continues, “I think that we have shown with CD-R that we can write with nearly the same robustness with which we can read CD,” and he expects CD-E to prove itself similarly sturdy.

Again, not everyone is in agreement on this point, given that the overall experience with writing well-handled multisession CD-R discs shows that only so much can be done to compensate for the degradation of the disc’s surface. In practice, not all recorders implement Running OPC. Some Running OPC schemes are better than others and some CD-ROM drive designs are more robust than others in their reading capabilities. Given that the data contained on a CD-E can be one of a kind, many may opt for the protection of a caddy system, regardless of any perceived inconvenience.

The question of using a caddy to protect unjacketed discs is not unique to CD-Erasable and has come up again in discussions surrounding the proposed DVD-RAM high-density rewritable format. The association of major computer industry companies known as the Technical Working Group (TWG) originally insisted there be no container for the media, but in light of technical evidence of the much smaller tolerances of DVD, the TWG has softened its position with the DVD Consortium to permit an optional cartridge or caddy.

CD-E MEDIA MANUFACTURERS: MORE MO THAN CD?

At the time of this writing, only Ricoh–upon whose media technology CD-E is based–has publicly announced that it will manufacture CD-Erasable discs. However, according to a Ricoh spokesperson, the company is discussing CD-E licensing with several interested manufacturers, including Mitsubishi/ Verbatim. According to Verbatim optical products manager Jim Riggs, Verbatim “anticipates that initial CD-E media production will begin in fourth quarter 1996, with continued expansion into 1997.”

According to Philips’ Klick, achieving a critical mass of CD-E media manufacturers is critical to the new format’s viability. “I think that as a prerequisite to introducing the product,” Klick says, “you should have a choice of at least three media companies. That’s essential.”

Unlike the CD-R media manufacturing process, which involves spin-coating technology, CD-Erasable media production uses a sputtering process similar to that used in the manufacture of traditional phase-change and magneto-optical (MO) discs. As a result, it is expected that the companies most interested in producing CD-Erasable discs will hail from the MO world rather than the CD-Recordable market. These early CD-E media market entrants could possibly include MO mainstays Kyocera, Imation, PDO, Maxell, Sony, Teijin, and others. Since Ricoh is not necessarily recognized as a competitive volume manufacturer, some insiders feel it is possible that Ricoh could form a manufacturing partnership to satisfy production needs.

Some industry observers, however, are a little more skeptical about the number of companies lining up to manufacture CD-E media. Industry analyst John Freeman, president of Strategic Marketing Decisions, says that manufacturers are concerned about multiple technologies today and the short-lived viability of many of them, so “no one wants to ramp up production for new ones.” Carl Rodia, president of Carl M. Rodia & Associates, a firm that designs, engineers, and commissions CD-ROM, CD-R, MO, and DVD automated manufacturing plants, says that there has been “little rush to get information on CD-E.” Rodia explains that “to the best of my knowledge, we have had only two inquires about CD-E, and those were simply as a passing footnote to potential CD-R manufacturers casually asking if their equipment could do it.” As a result, Rodia says, his company “has devoted little time towards new process development for CD-E.”

If sufficient and efficient CD-E production capacity is not forthcoming from several manufacturers, CD-E could face an uphill battle with regard to media pricing–something many observers have identified as being critical to CD-E’s health.

CD-Erasable media projections are a study in stark contrasts. Strategic Marketing Decisions projects very modest demands for CD-E while Ricoh Company predicts incredibly large and rapid growth for their products. Both anticipate, however, that DVD-ROM will dampen interest in CD-Erasable and prove its ultimate demise.

FITTING INTO THE MARKET

With the dizzying array of storage options available to computer users, including CD-R, PD, MO, Zip, Jaz, SyJet, EZ135, Syquest, QIC, Bernoulli, and LS-120 to name a few, the introduction of any new format automatically begs the question, why introduce another one? Why would someone consider adopting CD-E in preference to the alternatives, given the realities of CD-E that prevent it from being a good choice for a number of applications?

For example, in the case of data distribution, CD-E’s relatively high media cost and lack of read compatibility with existing CD-ROM drives and recorders make it an impractical option. As a reusable premaster source for CD-ROM mass replication, CD-E also disappoints, since commercial mastering equipment cannot read CD-E discs, and even if it could, errors created from the cumulative surface damage done to discs through repeated handling carries across to the final master. CD-E is also not an ideal solution for working with audio and MPEG video tracks, given that recording and rewriting are in a bulk rather than selective fashion. Furthermore, media defect maps are not maintained for avoiding damaged areas, and not all users’ systems are capable of sustaining the required double speed transfer rate needed for successful writing.

As a result, according to Philips’ Klick, CD-E will be marketed as a complimentary technology to CD-R, as opposed to its successor. Klick says Philips and its partners see “backup as the first and prime application target” for CD-Erasable, built upon the foundation of CD-Recordable. “We’ve seen CD-ROM title creation, archiving, and data interchange with CD-R,” Klick says, “but we’ve also encountered strong demands from the PC industry to have a rewritable function available for backup. If you look at the PC market, there are going to be a couple of slots available. One will stay with the floppy, and the other one is going to be a CD-ROM or CD-R or CD-Rewritable. Provided we meet a number of expectations, one of which is the price of the combination of hardware, software, and media, a significant part of the market which is CD-ROM-based now will, in a couple of years, move to CD-Rewritable.”

Philips’ van Eijk focuses on the comparison that is sometimes drawn between CD-E and other storage technologies and says that CD-E’s central value proposition is “inseparable from CD-R. We’re adding functionality to a CD-R drive,” he says. “That’s important because if you look at CD-Erasable by itself, there is a tendency to compare it as such to other technologies in the market that are erasable. The comparison is not so good because CD-E is neither a performance product nor a secondary hard drive, so let’s go back to what CD-R offers. In some applications, erasability would add functionality to a CD-R drive.” Backup is one instance where CD-E adds functionality, and another, van Eijk says, “is in multimedia development where people use a lot of media today, perhaps tens of discs sometimes, so erasability provides better economics for the user.”

Perry Solomon, president of popular CD-R bundler and reseller Smart and Friendly, says that erasability adds a “convenience factor that transcends cost, depending upon the application. We are seeing fantastic demands,” he continues, “for our current Phase-change Dual (PD) systems in graphic applications where large files change frequently, such as Internet Web pages where developers may need to update files on a daily basis. We expect similar uses for CD-Erasable.”

IS CD-E ONE FORMAT TOO MANY?

Some in the CD-Recordable industry hold that CD-E is not needed and represents nothing more than a distraction. To CD-E’s skeptics, CD-R is very well positioned to become a pervasive storage technology in spite of its write-once limitation. With the addition of packet writing, which will allow new information to be appended onto a disc, CD-R’s robustness, backward compatibility, high degree of interchangeability due to standards, and low media cost are all the necessary ingredients for an inexpensive, single-use technology described by some as “Digital Kleenex.”

According to its proponents, the notion of use-once technology follows an established tradition that is impossible to ignore. Writing paper, photographic film, disposable pens and lighters, floppy diskettes (which, though rewritable, are more often treated as disposable), and single-use cameras to name a few, provide a model of solid viability. Why, they say, introduce CD-Erasable when CD-R is already well-recognized and accepted in the marketplace as an inexpensive single-use technology?

Philips’ Klick agrees that CD-R is compelling in this light, but cautions that market segmentation cannot be overlooked. “If you look at the PC companies searching for the major applications in the home market, they tend more toward CD-R than CD-Rewritable. Those addressing more professional segments have a tendency toward a CD-Rewritable system, where you see a lot of influence from people who have been using 5.25-inch and 3.5-inch MO. The MO line of thinking favors CD-Rewritable.”

CMS’s Deane says his company has been “very proactive in CD-Erasable, and for good reason.” According to Deane, even before CMS introduced their first CD recorder, their “focus groups were saying it would be really great if you could reuse the disc. But when you tried to find out why, they couldn’t define the source of their inclination, but they wanted it just the same.” Deane suggests that CD-E’s potential users “have applications in mind for it like backup, moving files around the office, and taking data home and back to work. Erasability also addresses a psychological need,” he continues. “Many people aren’t used to thinking about their data storage in disposable terms.”

According to Deane, the experience of his company’s focus groups highlighted that while CD-Recordable will be very popular, the mass market targeted by his company “prefers rewritability because there is a glass ceiling that you bump up against with write-once.” The addition of CD-E to CD-R devices, they feel, will “make the market even bigger.” Philips’ van Eijk agrees that CD-E simply “adds value” to the CD recorder and enhances a good thing by providing additional options. CD-E, he says, is really “CD-R plus.”

Speaking privately, some others interested in the development of CD-E are less diplomatic and describe the decision to offer CD-E as a “no brainer,” and anticipate “that if all the pieces fall into place, pure CD recorders will disappear and CD-E will supplant CD-R as the medium of choice in the mass market.” Ricoh marketing figures projecting a potential market of hundreds of millions of CD-E discs support this view.

Others are more cautious in their assessment of CD-E. Strategic Marketing Decisions’ Freeman says that there are “limits to the market for CD-E” and expects that vendors bringing CD-E products to market will find “no margin for mispositioning. CD-E is really backup technology in place of QIC tapes,” he says, “not a performance file management tool.” His firm’s estimates are for media sales at least ten times smaller than some of Ricoh’s expectations.

Freeman is skeptical about the discussed pricing structure for CD-Erasable hardware as well, and as far as he is concerned, the companies “can’t charge a premium for CD-E.” The hardware, he says, must basically be a “gimmie” for purchasers. “Price is critical and drives must be $500 in the 4th quarter to be considered,” he adds. “Media pricing is the only thing that will make the technology viable, and it will be a challenge for CD-E media people to have low entry costs. Media must be $25 or less.” Further dampening CD-E’s market potential is the imminent introduction of DVD-ROM, and the release of DVD-R and DVD-RAM in a few years. “There’s not a big enough window of opportunity for CD-E,” says Freeman.

Again, there are differing opinions on the impact that DVD-ROM and its derivatives will have in the marketplace. In contrast to Freeman, Philips’ Klick says, “It is hard to predict exactly when the erasable DVD will be available. According to our forecasts and what the technology gurus inside Philips tell me, DVD-RAM sample products will show up in 1998, but in insignificant numbers in relation to the installed base. We believe that the window of opportunity to establish CD-R and CD-Rewritable is the year 2000. By then you will see significant numbers of DVD-ROM in the market, but still less than 10 million,” he continues. “We believe that CD-Rewritable will be a significant factor in the market by the year 2000, and that by then, we’ll see CD-Rewritable being sold in the 23 to 27 million volume.”

Also facing CD-E is the possibility of confusing purchasers with yet another compact disc format. Consumers’ general comfort with CDs is often cited as an advantage for CD-R and now CD-E, but that can easily be lost if the products fail to meet expectations. For example, users may perceive erasable CDs in the same way they think about regular CDs and floppy diskettes. But CD-E discs are not really interchangeable like CDs, and unlike floppies, may need to be defragmented to reclaim unused space after writing. Is this what users have in mind when they think of erasability? According to CMS’s Dean, “The trick is to set the customer’s expectations properly.”

Similarly, is it clear when a user should write to CD-E instead of to CD-R? Which specific marketing or product implementations of CD-E will be taken have yet to be decided, but Philips’ van Eijk is confident that there are ways to anticipate and avoid the problems. “We have to do some system design work to make the decision transparent to the user,” he says, “and that’s one thing we have to do before October 1.” It can be done, he adds, “perhaps with what the software tells you or a combination of color and logo, but I agree that just having the wording CD-Rewritable versus CD-R is not going to be sufficient. Nobody reads the manual to find out exactly what that means.”

All these concerns and opinions remain to be further explored in light of ongoing concrete experience. Nonetheless, CD-Erasable arrives with great promise and may represent a remarkable technical advance, especially if concerns over cost and backward/forward compatibility are overcome.

But is it good enough and refined enough yet to establish its role and value with users and to be considered worthwhile by computer manufacturers for installation in their future product lines? Will CD-Erasable become the guaranteed success and “no brainer” the industry promoters claim, or will it just be remembered as “Vapordisc” revisited? And will it finally close the book on rewritable CD technology or once again fade into obscurity to be reworked and refined for later resurrection when it can truly accomplish the requirements it should seek to satisfy?

What to Call It?

What to Call It?

As part of the marketing strategy for CD-Erasable, a name change is expected. The most popular suggestion appears to be CD-Rewritable, though some industry observers are critical, saying that it confuses the marketplace, since CD-Rewritable does not share the same characteristics as other rewritable media. No public rational has been given for creating a new name for CD-E, other than that “rewritable” may eliminate any possible negative connotations surrounding the term “erasable.”

Testing Equipment

For companies seriously involved in CD-Erasable product development, a few test systems are currently available from license holders Philips and Sony.

Since it is possible to modify existing CD-ROM and CD-R test equipment to accommodate CD-E, some manufacturers like Koch International, StageTech, Audio Development, and CD Associates say that they are seriously investigating support of the new format. Due to CD-E’s orientation as an in-house storage format rather than a data distribution medium, CD Associate’s vice president of product development, Mark Worthington, says he expects to release a device “much like our SL25 CD-R Analyzer, which is a lower-cost device appropriate for integrating into medical, legal, or other sensitive applications.” Clover Systems says they are more cautious about the size of demand for CD-E and not in a great rush to add CD-E functionality. They are taking a wait-and-see approach.

One test equipment manufacturer who has already taken the plunge is Apex Systems, Inc., a subsidiary of CD manufacturing system giant ODME B.V. Apex offers a research and development and quality assurance-grade CD-Erasable tester. The company’s new $135,000 OHMT-550 device is a modified version of their standard OHMT-500 CD-Recordable analysis system. An upgrade is available to existing OHMT-500 customers to add CD-E capabilities. They will also have higher volume test equipment with multiplexing capabilities and the ability to test six discs simultaneously.

Directory of CD-Erasable Products

Directory of CD-Erasable Products

CD-E SYSTEMS

• Hewlett-Packard

• Ricoh Company, Ltd.

• Philips Electronics

• Yamaha Corporation

Philips, Ricoh, and Hewlett Packard are expected be the first companies to offer CD-E recorders, with shipping dates tentatively planned for the end of 1996 or the beginning of 1997. The first round of products will most likely be SCSI devices with 2X write and either 4X or 6X read capabilities with mainstream appeal and bundled for a mass-market audience. Yamaha has also discussed products for introduction in the first or second quarter of 1997. Philips’ position as the dominant supplier of components, however, suggests that many CD recorder manufacturers will quickly follow suit in adding CD-E capabilities.

“CD-E-ENABLED” CD-ROM DRIVES

• Philips Electronics

• Mitsumi Electronics Corporation

So far the only company who officially says they will offer CD-E “enabled” or “multi-read” CD-ROM drives is Philips, although unofficially Mitsumi plans to add CD-E read functions to their next generation 8X or 10X ATAPI CD-ROM drives for introduction in the first or second quarter of 1997. Given the highly competitive nature of the market, industry experts expect that most CD-ROM drive manufacturers will only add CD-E read capabilities if PC computer manufacturers require it when buying their products. Matsushita and Sony, the other companies who control the vast majority of the CD-ROM drive market, are as yet uncommitted.

BLANK DISCS

• Ricoh Company, Ltd.

• Mitsubishi Chemical Company/Verbatim Corporation

For the immediate future, there will be only two companies manufacturing blank CD-E discs. Ricoh is expected to offer their products housed in caddies called “CD-Cassettes,” and Verbatim will most likely make available its parent company’s discs under their own label. So as to serve and maintain brand loyalty among customers, others may choose to purchase discs from either manufacturer for rebranding. For example, KAO Infosystems already sources CD-R media from Ricoh, and Pinnacle Micro from Mitsubishi, so it would be natural to extend their relationships to include CD-E media. Prices are expected to start in the $25 range.

Although it is technically possible to manufacture both 8cm (18 and 21-minute) and 12cm (63 and 74-minute) CD-E discs, given the experience of the CD-Recordable market, it is likely that the companies will choose to sell only a 12cm 74-minute version.

TEST EQUIPMENT

• Apex Systems, Inc.

• Philips Electronics N.V.

• CD Associates, Inc.

• Sony Corporation

The first test equipment made available for CD-E development work was introduced by Philips and Sony, the licensers of Orange Book Part III. Apex Systems produces and sells a research and development and quality assurance grade, while CD Associates says they are planning a more modest device applicable for offices needing disc verification. Others are showing interest, but are assessing whether there will be sufficient demand.

Companies Mentioned in This Article

Apex Systems, Inc.

2400 Central Avenue, Suite A, Boulder, CO 80301;

303/443-3393; Fax 303/443-4974

Carl M. Rodia & Associates, Inc.

13 Locust Street, Trumbull, CT 06611;

203/261-1365; Fax 203/268-1619

CD Associates, Inc.

15375 Barranca Parkway, Suite I-101, Irvine, CA 92718;

714/733-8580; Fax 714/453-0868

Colorado Memory Systems Division

Hewlett Packard Company, 800 South Taft Avenue, Loveland, CO 80537;

800/810-0134; 970/635-1500; Fax 970/667-0997;

www.hp.com

Eastman Kodak Company

343 State Street,Rochester, NY 14650;

800/235-6325;

www.kodak.com

Philips Key Modules

2099 Gateway Place, Suite 100, San Jose, CA 95110;

408/453-7373; Fax 408/453-6444;

www.keymodules.philips.com

Ricoh Company, Ltd.

DMS Division, 3-2-3 Shin-yokohama, Kohoku-ku,

Yokohama City 222, Japan;

+81-45-477-1601; Fax +81-45-477-1597

Smart and Friendly, Inc.

20520 Nordhoff Street, Chatsworth, CA 91311;

818/772-8001; Fax 818/772-2888;

www.smartandfriendly.com

Strategic Marketing Decisions

61 E. Main Street, Suite C, Los Gatos, CA 95032;

408/395-5159; Fax 408/395-1569

Verbatim Corporation

1200 W.T. Harris Boulevard, Charlotte, NC 28262;

800/759-3475; 704/547-6628; Fax 704/547-6609;

www.verbatim.com

Orange Book Part III is available from:

Philips Consumer Electronics

Coordination Office Optical & Magnetic Media Systems,

Building SWA-109, P.O. Box 80002,

5600 JB Eindhoven, The Netherlands;

Fax +31-40-732113

Author’s note

I wish to thank the Eastman Kodak Company, Hewlett-Packard Company, Philips Electronics N.V., Ricoh Company Ltd., and the persons mentioned in the text for their assistance in the preparation of my article.

About the Author

Hugh Bennett, editor-in-chief of Hugh’s News, is president of Forget Me Not Information Systems, a reseller, systems integrator and industry consultant based in London, Ontario, Canada. Hugh is author of The Authoritative Blu-ray Disc (BD) FAQ and The Authoritative HD DVD FAQ, available on Hugh’s News, as well as Understanding Recordable & Rewritable DVD and Understanding CD-R & CD-RW, published by the Optical Storage Technology Association (OSTA).

Copyright © Online Inc. / Hugh Bennett