Sony Corporation announced it, in concert with IBM Research, has developed a magnetic tape storage technology with a recording areal density of 201 Gb/in2.

Sony Corporation announced it, in concert with IBM Research, has developed a magnetic tape storage technology with a recording areal density of 201 Gb/in2.

For more information visit: www.sony.com ; www.ibm.com

Unedited press release follows:

Sony Develops Magnetic Tape Storage Technology with the Industry’s Highest*1 Recording Areal Density of 201 Gb/in2

20x Greater Density Than Conventional Technology*2 for Supporting High-Capacity 330 TB*3 Recording

Sony Corporation

Sony Storage Media Solutions Corporation

Tokyo, Japan — Sony Corporation (“Sony”) today announced that it has developed, in collaboration with IBM Research, located in Zurich, Switzerland, a magnetic tape storage technology with the industry’s highest*1 recording areal density for tape storage media, at 201 Gb/in2 (gigabits per square inch). This achievement was made possible by bringing together Sony’s new magnetic tape technology employing lubricant with IBM Research – Zurich’s newly developed write/read heads, advanced servo control technologies and innovative signal-processing algorithms. The recording areal density of 201 Gb/in2 is approximately 20x greater than conventional*2 magnetic tape storage media (9.6 Gb/in2). The resulting technology can support high-capacity storage of approximately 330 terabytes (TB)*3 per data cartridge, whereas conventional technology can only handle 15 TB per data cartridge.

These development results were jointly announced with IBM Research – Zurich on Wednesday, August 2, 2017 at The 28th Magnetic Recording Conference (TMRC 2017) at the Tsukuba International Conference Center in Tsukuba, Japan.

*1 On magnetic tapes. As of announcement on August 2, 2017.

*2 When compared with the IBM TS1155 tape drive, JD cartridge (non-compressed), the newest enterprise-class tape system.

*3 Assuming the same format overheads as the TS1155 format and taking into account the 6.4% increase in tape length enabled by the thinner demo tape. A TS1155 JD cartridge, can hold 15 TB of uncompressed data in a 4.29 in. x 4.92 in. x 0.96 in. (109.0 mm x 125 mm x 24.5 mm) form factor.

In recent years, developments in the Internet of Things, the popularization of cloud services, and the leveraging of big data have helped to create new markets, resulting in increased demand for high-capacity data storage media. Moreover, the importance of data storage is being reaffirmed in terms of ensuring reliable recovery of data in information systems such as databases and servers, as well as safe management of information. It is against this background that magnetic tape shows great potential as a storage media thanks to its various strengths, including its capacity for storing data over long periods of time, low power consumption, low cost, and space saving capabilities.

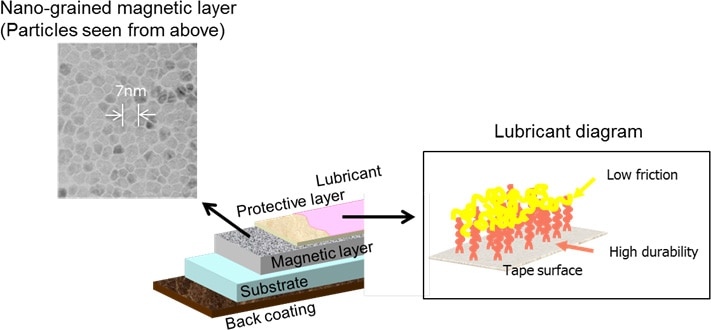

Closing the gap (spacing) between the magnetic tape and magnetic head is critical to achieving high-density recording capabilities for tape storage media. Reduced spacing entails increased friction at contact points between the tape surface and magnetic head, however, friction must be reduced and the tape surface must smoothly run along the magnetic head to enable high-capacity writing and reading at a high speed. Upon establishing this new magnetic tape technology, Sony developed a lubricant that is applied between the tape surface and magnetic head. This low-friction lubricant not only reduces friction between the tape surface and magnetic head, but also features a highly durable bond between the lubricant and magnetic layer of the tape.

Furthermore, this new technology made it possible to create a nano-grained magnetic layer*4 with microscopic magnetic particles in extended tape length. Conventionally, a common problem is non-uniform crystalline orientation and disparities in grain sizes due to impurity gas generated from the surface of equipment during magnetic layer formation. A newly developed processing technology that reduces impurity gas is used in conjunction with sputter deposition,*5 a method of forming a nano-grained magnetic layer with an average grain size of 7 nm, thereby resulting in extended tape length. With these advancements in processing technology, the foundation has been laid for production of tape storage cartridges that can hold more than 1000 meters of tape.

Combining this magnetic tape technology together with IBM Research Zurich’s write and read heads, advanced servo control technologies and innovative signal-processing algorithms, Sony has achieved the industry’s highest*1 recording areal density of 201 Gb/in2 — about 20x greater than the current*2 mainstream coated magnetic tape media for data storage.

*4 Nano-grained magnetic layer: Sony original thin layer tape formation technology which forms a layer of uniform, nanometer-scale magnetic particles on the substrate. The technology features optimized sputter conditions which minimize surface unevenness on the substrate, resulting in a uniform deposition of microscopic magnetic particles.

*5 Sputter deposition: A thin layer formation method where electrostatic discharge is used to force argon (Ar) ions to collide with the source material (target), and the sputtered material forms a deposition on the substrate to create a thin layer.

Sony will build on this new development to forge ahead with development of magnetic tape technologies, aiming to commercialize next-generation tape storage media capable of high-capacity data recording and achieve even higher recording density.