NPD DisplaySearch announced its latest research suggests that AMOLED TV prices will remain sky high for the foreseeable future.

NPD DisplaySearch announced its latest research suggests that AMOLED TV prices will remain sky high for the foreseeable future.

For more information visit: www.displaysearch.com

Unedited press release follows:

New AMOLED TV Costs Ten Times More than LCD TV to Produce

Manufacturing Costs Expected to Reach Parity in the Long-Term; AMOLED Market Forecast to Reach 22M Square Meters in 2016

SANTA CLARA, Calif., August 8, 2012—Active-matrix organic light-emitting diode (AMOLED) represents a rapidly growing and highly promising technology for all display applications. Based on planned investments, NPD DisplaySearch forecasts that the market will grow nearly tenfold from 2.3M square meters in 2012 to more than 22M in 2016.

Most AMOLED capacity is currently dedicated to small/medium production for smart phones, but much of the capacity increase going forward is expected to be driven by fabs dedicated to TV production. There are many unknowns about how far and how fast it will develop, though, since AMOLED technology has not yet been proven in large-size TVs.

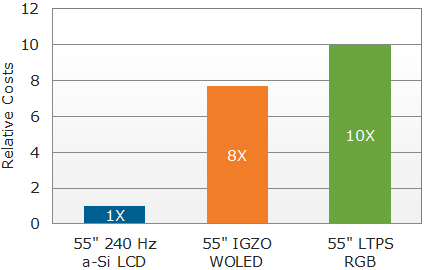

According to the NPD DisplaySearch AMOLED Process Roadmap Report, the manufacturing cost of a 55” oxide TFT-based AMOLED using white OLED with color filters is 8 times that of a high-end 55” TFT LCD display of equal size. The cost multiplier of a 55” AMOLED module using red, green, and blue OLED is 10 times. These higher costs are mainly a result of low yields and high materials costs.

Jae-Hak Choi, Senior Analyst, FPD Manufacturing for NPD DisplaySearch, noted, “While cost reduction in LCDs has slowed, large panel AMOLED cost reduction is in its infancy. In the long-term, new and improved processes, printing technology, and higher performance materials will reduce AMOLED costs to levels equal to or lower than LCD.”

Figure 1: Relative Manufacturing Costs of Technologies for 55” TV Panels

Source: NPD DisplaySearch AMOLED Process Roadmap Report

Note: Based on current yield and material cost assumptions. IGZO: indium gallium zinc oxide. WOLED: white OLED with color filters. LTPS: low temperature polysilicon. RGB: red, green, blue (direct emission) OLED.

Due to greater process maturity, the manufacturing cost premium for a 4” AMOLED is less than 1.3 times that of a similar-sized LCD. Samsung Display has been highly successful in its small/medium AMOLED production because it has been able to raise yields to near-LCD levels. This implies that manufacturers can potentially lower large size AMOLED TV costs to be competitive with LCD TVs in the future.

In order to scale up to large sizes, advancements in several aspects of AMOLED manufacturing are needed, including the active matrix backplane, organic material deposition, and encapsulation. Because oxide TFT requires lower capital costs and is similar to existing amorphous silicon TFT, it offers a strong alternative to the low-temperature polysilicon (LTPS) TFT currently used for AMOLED. However, there are many hurdles for mass production of oxide TFT, particularly threshold voltage shifts, which are continuing to prove problematic for AMOLED production.

While indium gallium zinc oxide (IGZO) and other forms of oxide TFT show great promise for backplanes, progress in scaling up LTPS production is also being made by increasing the excimer laser beam width to 1300 mm. In addition, the current method of depositing red, green, and blue materials by evaporation through a fine metal mask is being continuously improved. Pixel densities of 250 ppi are now possible, and over 280 ppi is feasible.

“Despite these advancements, high resolution continues to be a relative weakness for small/medium AMOLED compared to LCDs. High resolution patterning such as laser induced thermal imaging (LITI) and material improvements are still required for AMOLED to be highly competitive for super high resolution flat panel displays,” Choi added.

The NPD DisplaySearch AMOLED Process Roadmap Report provides in-depth data and analysis on OLED manufacturing technologies including materials, backplanes, OLED, and encapsulation. It also includes an analysis of benefits, opportunities, negatives, and challenges for each technology. Unique to the industry, the report shows specification roadmaps for OLED manufacturing through 2016 and indicates which manufacturing technologies will be required to achieve stability and performance. Also, the report provides a unique equipment investment simulation and module cost modeling analysis. For more information on the report or for further assistance, please contact us at +1.408.418.1900, sales@displaysearch.com, or at the local DisplaySearch offices in China, Japan, Korea, Taiwan, and the UK.

About NPD DisplaySearch

Since 1996, NPD DisplaySearch has been recognized as a leading global market research and consulting firm specializing in the display supply chain, as well as the emerging photovoltaic/solar cell industries. NPD DisplaySearch provides trend information, forecasts and analyses developed by a global team of experienced analysts with extensive industry knowledge. In collaboration with The NPD Group, its parent company, DisplaySearch uniquely offers a true end-to-end view of the display supply chain from materials and components to shipments of electronic devices with displays to sales of major consumer and commercial channels. For more information on DisplaySearch analysts, reports and industry events, visit us at http://www.displaysearch.com/. Read our blog at http://www.displaysearchblog.com/ and follow us on Twitter at @DisplaySearch.

About The NPD Group, Inc.

The NPD Group is the leading provider of reliable and comprehensive consumer and retail information for a wide range of industries. Today, more than 2,000 manufacturers, retailers, and service companies rely on NPD to help them drive critical business decisions at the global, national, and local market levels. NPD helps our clients to identify new business opportunities and guide product development, marketing, sales, merchandising, and other functions. Information is available for the following industry sectors: automotive, beauty, entertainment, fashion, food, home and office, sports, technology, toys, video games, and wireless. For more information, contact us or visit npd.com and http://www.npdgroupblog.com/. Follow us on Twitter: @npdtech and @npdgroup.