Much like the military remnants of the cold war, Kodak’s expensive PCD Writer 600 is trying to find an alternate role in a new world order — a recorder culture dominated by entry-level units. But comparing the PCD Writer 600 to any other CD recorder is like comparing the old Army Jeep to a Hummer, or a trip to the go-cart track to the Indy 500.

Much like the military remnants of the cold war, Kodak’s expensive PCD Writer 600 is trying to find an alternate role in a new world order — a recorder culture dominated by entry-level units. But comparing the PCD Writer 600 to any other CD recorder is like comparing the old Army Jeep to a Hummer, or a trip to the go-cart track to the Indy 500.

Kodak’s PCD Writer 600 and Disc Transporter: Replication in Record Time

Hugh Bennett

CD-ROM Professional, July 1995

Originally intended as a breakthrough boon to Photo CD processing labs, the Kodak PCD Writer 600 (PCD 600) is an extraordinary piece of equipment whose importance to Eastman Kodak Company’s multimedia manufacturing program has shifted now that Photo CD has failed to attract wide consumer acceptance. Much like the military remnants of the cold war, the expensive PCD 600 is trying to find an alternate role in a new world order — a recorder culture dominated by entry-level units. But comparing the PCD 600 with any other CD-Recorder is like comparing the old Army Jeep with a Hummer, or like comparing a trip to the go-cart track to the Indy 500.

Originally intended as a breakthrough boon to Photo CD processing labs, the Kodak PCD Writer 600 (PCD 600) is an extraordinary piece of equipment whose importance to Eastman Kodak Company’s multimedia manufacturing program has shifted now that Photo CD has failed to attract wide consumer acceptance. Much like the military remnants of the cold war, the expensive PCD 600 is trying to find an alternate role in a new world order — a recorder culture dominated by entry-level units. But comparing the PCD 600 with any other CD-Recorder is like comparing the old Army Jeep with a Hummer, or like comparing a trip to the go-cart track to the Indy 500.

The PCD 600, built for speed and endurance, represents the state of the art in commercially-available CD-ROM recording devices. The industry’s first 6X, “hex speed” system, it writes a full 74-minute disc (650MB) in less than twelve minutes — eight minutes faster than its nearest quad speed competitor. Not only does the unit write discs much faster than other systems, it does so more reliably, and ultimately produces higher quality discs. The PCD 600, furthermore, is constructed to make hundreds of them at a sitting without damaging the mechanism. What makes Kodak’s accomplishment even more amazing is the fact that the PCD 600 was designed entirely by Kodak. Not a bad first try!

Coupled with the Disc Transporter (an autoloader which attaches to the recorder and enables unattended recording of up to 75 discs at a time), the PCD 600 is a potent solution for low-run replication, CD-ROM publishing on demand, data distribution, Computer Output to Laser Disc (COLD), network CD-ROM production, and off-line archiving.

As might be expected, all this power comes at a relatively high cost. Currently, Kodak lists the PCD 600 for $28,995 and the Disc Transporter for $7,750. All indications are that they will not be reducing these figures significantly any time soon. For what the PCD 600 does, the price is not out of line, but for most CD-R users, the PCD 600 will remain the stuff of over-priced, over-engineered, and over-built dreams.

WHAT’S IN THE BOX?

The PCD 600 is a relatively large device, with dimensions of 15″ (long) by 17.1″ (wide) by 5.8″ (high), and weighing in at 27 pounds. This CD-Recorder nonetheless bares a striking, if somewhat swollen, resemblance to its double speed cousins; the backplane contains two high-density 50-pin single-ended SCSI connectors, a bank of DIP switches for selecting the SCSI device ID number and setting switchable internal termination, the power connector for the auto switching 100-240 VAC, 50-60Hz universal power supply, and a replaceable foam air filter. The front panel is just as straightforward. There is an open/close button for the disc tray and power, ready, busy, and error indicator lights.

As the unit is intended for integrators to sell as part of a solution, no additional hardware or software is included with the package. Consequently, a number of enabling items such as SCSI cabling, a SCSI controller (if necessary) and premastering/mastering software must be added. Users and resellers should also take into consideration that the recorder’s high air flow fan, designed to cool the unit during constant use, is very noisy and could be disruptive in an otherwise quiet environment.

If the PCD 600 is considered large, then the Disc Transporter can only be described as huge, at 21″ (long) by 21.6″ (wide) by 16.5″ (high), and weighing 47 pounds. Like the PCD 600, the back of the Transporter contains two high-density 50-pin single-ended SCSI connectors, a bank of DIP switches for selecting the SCSI device ID number and setting switchable internal termination, and the power connector for its auto switching universal power supply. The front face contains a reset button and a vertical strip of operational status LEDs for power, ready, end of batch, disc attention, input attention, output attention, and error. (Transporters can also be attached to Kodak’s 2X PCD Writer units and the Philips CDD521 double speed recorder, with the use of a separately sold adapter kit.)

If the PCD 600 is considered large, then the Disc Transporter can only be described as huge, at 21″ (long) by 21.6″ (wide) by 16.5″ (high), and weighing 47 pounds. Like the PCD 600, the back of the Transporter contains two high-density 50-pin single-ended SCSI connectors, a bank of DIP switches for selecting the SCSI device ID number and setting switchable internal termination, and the power connector for its auto switching universal power supply. The front face contains a reset button and a vertical strip of operational status LEDs for power, ready, end of batch, disc attention, input attention, output attention, and error. (Transporters can also be attached to Kodak’s 2X PCD Writer units and the Philips CDD521 double speed recorder, with the use of a separately sold adapter kit.)

Included with the Transporter is a high-density 50-pin to high-density 50-pin SCSI cable necessary to connect the unit to the back of the recorder, as well as two empty disc spindles (additional spindles are available from Kodak). Anyone planning to add a Transporter for the office should be aware that it also makes considerable mechanical noise when in operation.

A FAST RECORDER NEEDS A FAST COMPUTER

Recording at hex speed requires a sustained data transfer rate of 921.6KB/sec for Mode 1 and 1058.3KB/sec for Mode 2 or CD-DA sectors, so the PCD 600 should be matched to an appropriately fast host system. For reliable on-the-fly recording, realistic PC users should consider a Pentium class machine with an Adaptec 2940 PCI SCSI controller (a second adapter does not hurt) and a 2 gigabyte or larger SCSI hard disk drive specifically designed for audiovisual (AV) use. Macintosh configurations, however, are another story.

Since the only Mac software package available with support for the PCD 600 records only physical images, the demands upon the system are not as great. Thus, Mac users can technically get away with using less powerful hardware. For example, during testing a Macintosh Centris 660AV and a new non-AV Hewlett-Packard 1.0GB hard disk had no problem recording physical images or CD-DA tracks at hex speed. It is more likely though that users will want to invest in a Power Macintosh 8100 series computer with an AV hard disk connected at least to the CPU’s second internal SCSI II Fast channel.

The PCD 600 offers a standard 2MB buffer that can be expanded to either 4MB or 8MB by using extra static RAM (not DRAM) kits available through Kodak. Some might question the wisdom behind providing only a stock 2MB buffer, but it must be remembered that Kodak intends the PCD 600 to be sold by integrators who carefully match and configure the recorder to a host system and specific application.

WRITING ROUTINE AND SUBCODE SUPPORT

Like many current CD-Recorders, the PCD 600 offers both Track-At-Once (TAO) and Disc-At-Once (DAO) recording methods. If the feature is recognized by the premastering/mastering software, DAO allows the writing of Red, Yellow, and Green Book CDs that more closely resemble stamped discs. For example, with audio CDs, the run-in, run-out, and link blocks between tracks that are characteristic of Orange Book writing are eliminated and make the final product more desirable for mastering and replication. Variable track spacing is another appeal of DAO as the pause between audio tracks can be altered beyond the fixed two second gap required by TAO recording.

Also of interest for those doing audio work, Kodak says the PCD 600 supports PQ subcode encoding, a function not tested in this review. Information such as copy prohibit, pre-emphasis, ISRC (International Standard Recording Code) and UPC/EAN (Uniform Product Code/ European Article Number) media catalog numbers can be saved in the Q subcode channel. Audio index points are not offered by the current PCD 600 firmware.

CD-ROM DRIVE PERFORMANCE

If your premastering/mastering software includes the necessary device driver, the PCD 600 can be used as a standard CD-ROM drive. With a sluggish average access time of 1000ms, a heart-stopping sustained transfer rate of approximately 900KB/sec, and utilization of the full buffer (2, 4 or 8MB), the reading capabilities are intended more for data copying and verification than for playing multimedia games.

Digital audio extraction is also possible at 2X and 6X speeds, so Red Book audio tracks can be read quickly from a disc in the unit, transferred across the SCSI bus and saved as files on a hard disk drive for later recording or incorporation into other projects.

FIRMWARE IN A FLASH

An important feature available on the PCD 600 is software-upgradable firmware. Instead of the dealer or manufacturer replacing chips whenever there is an enhancement or bug-fix to the recorder, Kodak issues a CD-ROM that contains the changes, which the user needs only to insert to make the system update itself.

Each PCD 600 also contains an internal communications port with which an on-site service agent can access and establish a remote telephone link between the recorder and a Kodak technician. Diagnostic and operational logs can then be downloaded, examined, and a course of action considered. This may involve simply uploading a few firmware tweaks back to the recorder, rather than sending the unit into a depot for service. The field upgradability and remote diagnostic capability of the PCD 600 give it a distinct advantage over other recorders in high volume or critical production environments.

TRACKING DOWN DISCS WITH BARCODES

TRACKING DOWN DISCS WITH BARCODES

The PCD 600 shares the ability of all Kodak CD-Recorders to read either the unique 12-or 16-digit barcode present on any Kodak Writable CDs and make the number available to the premastering/mastering software.

Packages that support the barcode feature normally enter the value into a log file so users can easily identify CD-ROMs and write it to the final disc in accordance with Photo CD specifications. According to Kodak, barcode values must be recorded in the Application Use area of the Primary Volume Descriptor (PVD)–sector 16, bytes 1055 to 1066 for 12-digit barcodes or sector 16, bytes 1055 to 1070 for 16-digit barcodes.

Once on the disc, the barcode acts as a serial number that can be accessed by any application designed to look at the PVD. There are a lot of practical uses for the coding system. For example, a CD-ROM publisher producing limited edition software might use it as a method of copy protection; a bank or police agency could also use the number as a security measure to help verify the authenticity of discs that contain investigative or financial records and COLD files.

THE SUPPORTING CAST: PREMASTERING SOFTWARE

A CD-Recorder is only as good as the premastering/mastering software used to control it, and the PCD 600 is no exception. A lot of solid applications and complimentary hardware are available from Kodak and other vendors, but something that became painfully obvious during the course of this review was that just because a software company claims their package works with the PCD 600 and Transporter, does not necessarily mean that it does so very well. Thus, interested parties must be cautious in selecting enabling products.

One set of difficulties relates to hardware features supported by the software. A package may work with the PCD 600, but may not exploit all of the unit’s capabilities such as DAO and barcode reading, or only perform digital audio extraction at 2X instead of 6X.

Companies who tout PCD 600 compatibility should have a unit available on an ongoing basis for duplicating customer problems and to assist in offering satisfactory technical and troubleshooting assistance. Similarly, recorders undergo periodic firmware changes that may create incompatibilities between the hardware and software. During the course of this review, Kodak updated the firmware from 3.2 to 3.3. Developers without access to a unit cannot keep their applications current, so that one key software evaluation criterion may be whether or not the premastering manufacturer has the appropriate Kodak hardware in-house.

Software and Hardware Supporting the Kodak PCD Writer 600 and Disc Transporter

| DOS | Windows | Mac | OS/2 | Sun OS | Solaris | HP | SGI | DG | RS-6000 | DEC | |

| Astarte | RT | ||||||||||

| Dataware | RT | RT | RT | ||||||||

| Elektroson | RT | RT | RT | RT | RT | RT | RT | RT | |||

| Kodak | RTB | ||||||||||

| OptImage | RT | ||||||||||

| Rimage | RT | ||||||||||

| Smart Storage | RTB | RTB | RTB | RTB | |||||||

| Young Minds | RTB | RTB | RTB | RTB | RTB | RTB | RTB | RTB |

Legend

R PCD Writer 600 CD-Recorder support

T Disc Transporter support

B Bar code support

YOUNG MINDS

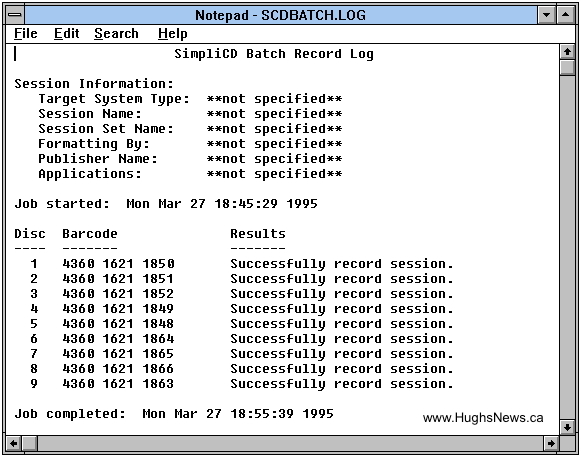

Young Minds, Inc. offers several products that directly support the PCD Writer 600. SimpliCD 2.4 for Windows is relatively easy-to-use entry level premastering/ mastering software that creates ISO 9660 Mode 1, single or multitrack; mixed-mode; CD-DA; ISO 9660 Mode 2, Form 1, “Kodak-style”; and multivolume multisession discs. An optional addition to SimpliCD is also available for upgrading the software to support the Disc Transporter.

In addition, the company offers their turnkey CD Studio UNIX solution for SunOS, Solaris, HP, SGI, RS-6000, and DEC Alpha platforms. Three components make up the CD Studio: MakeDisc premastering/mastering software, a CD Studio intelligent controller, and the CD-Recorder itself. The system is operated through UNIX command line or either a Motif or OpenLook Graphical User Interface (GUI), and creates UNIX File System (UFS) and ISO 9660 with Translation tables or Rock Ridge Extensions disc types. All of the solutions support the PCD 600, Transporter, and disc barcodes.

ASTARTE AND OPTIMAGE

ASTARTE AND OPTIMAGE

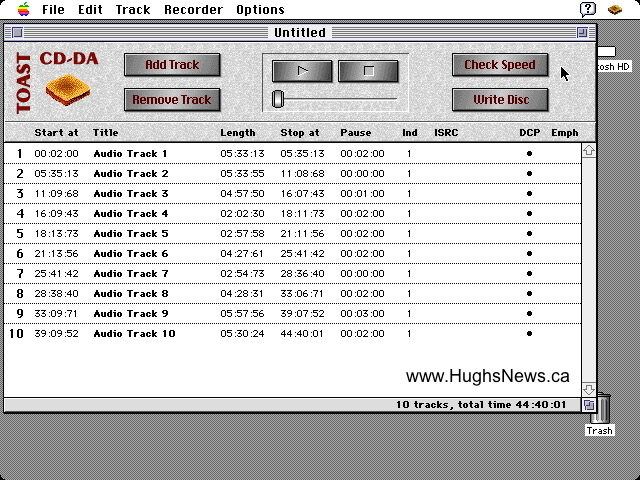

Astarte’s Toast CD-ROM Pro 2.5.2 and Toast CD-DA 1.6.1 and OptImage’s CD-IT!ALL 2.5.2 — an OEM version of Toast CD-ROM Pro — are currently the only Macintosh premastering/mastering packages that support the PCD Writer 600 and Disc Transporter.

Both Toast CD-ROM Pro and CD-IT!ALL are full-featured software packages that create all popular disc types: ISO 9660 with or without Apple Extensions, HFS, Video CD, CD-i, hybrid, Enhanced CD (CD Plus), XA, CD-DA, mixed-mode, and generic and Kodak-style multivolume multisession. In contrast, Toast CD-DA 1.6.1 is an application specifically designed for premastering Red Book audio compact discs. The package records 44.1KHz, 16-bit AIFF, and SoundDesigner II (SDII) audio files in DAO mode, and permits PQ subcode editing.

ELEKTROSON

Another mainstay of the CD-Recordable market is Elektroson. They offer PCD 600 and Transporter support in their GEAR 3.2 software for several platforms, including Windows, OS/2, SunOS, Solaris, HP, SGI, and DEC.

GEAR is available in a non multi-media version for basic Mode 1 ISO 9660 and CD-DA disc creation as well as a full multimedia package that generates a wide range of disc types, among them ISO 9660, UFS, Rock Ridge, CD-DA, mixed-mode, XA, CD-i, Video CD, and Kodak-style and multivolume multisession.

DATAWARE

Dataware Technologies’ latest 2.2 version of CD Record for Windows, MS-DOS, and SunOS now support the PCD 600 and Transporter. Since Dataware also OEMs CD Record to other companies, anyone selling repackaged versions will no doubt offer the same enhancement.

CD Record Lite software offers basic ISO 9660 with or without Apple Extensions and Kodak-style multisession disc creation while a Standard version adds CD-i, Video CD, XA, CD-DA, MMCD, and mixed-mode formatting.

SMART STORAGE

Smart Storage of Andover, Massachusetts sells a DOS-based package called SmartWrite CD-HV 1.0 that operates under a different concept than most premastering software. In addition to offering standalone host creation of ISO 9660 with or without Apple Extensions, HFS, and ISO/HFS partitioned CD-ROMs, SmartWrite also allows network users to generate their own discs.

When configured as a dedicated server on a PC or NFS network, SmartWrite processes and queues node requests to create CD-ROMs in a manner similar to a print server. Much as a user would send a print job to a network laser printer, clients using Windows, Mac, or Solaris can send their job to the server for recording. And just as a sheet feeder makes it unnecessary to manually feed paper a piece at a time, so the Transporter frees the administrator from loading and removing every disc.

EASTMAN KODAK

Writable CD Production Station Publishing Software and Direct-Write by Kodak let SunOS users create ISO 9660 discs in either Mode 1 or Mode 2, Form 1 formats. The Publishing package is intended for easy premastering and offers useful features such as job queuing for unattended batch writing and operation on multiple hosts not directly connected to the PCD 600.

Direct Write, on the other hand, provides an Application Programmer’s Interface (API) that developers can use to integrate CD-Recording capabilities into their own software. Companies like EDS Document Processing Services have already used Direct Write to integrate CD-Recordable output functions into their COLD and information management systems.

AND LABELS, TOO

AND LABELS, TOO

An enduring problem with CD-Recordable has always been how to label a finished disc in an efficient and attractive manner. Rimage Corporation’s answer is its new CD-R Printer.

Unlike slower inkjet printers from Trace and Craig International, the CD-R Printer uses thermal transfer technology to print 300dpi labels directly on the face of a disc at an average of four per minute. It operates either as a standalone unit or attaches to the front of the Transporter to allow CD-Rs to be recorded and printed in sequence. A reject area accepts problematic finished discs.

When configured in this in-line position, the PCD 600, Transporter, and CD-R printer offer a unique disc production alternative to small run replication. Why have a small run of 50 CD-ROMs manufactured when you can produce and professionally label them yourself in a fraction of the time for a similar price? Another question to ask: why would a replicator use their main production lines for 100 discs when a turnkey CD-Recordable system will do it more cost-effectively?

A DISC AT ANY OTHER SPEED

Writing a CD-ROM at “hex speed” is not a simple matter and presents a number of technical challenges. Any time there is a shift in CD-Recording speed there must be, among other things, corresponding changes in the blank media and the way in which the CD-Recorder approaches writing the disc.

In its efforts to help ensure that CD-ROMs will be recorded correctly, Kodak specifically recommends their own media be used in the PCD 600. A cynic might say that Kodak is just interested in selling their own Writable CDs, but there are good reasons to be cautious in choosing blank media for the system. Beside offering the barcode feature that is useful for disc identification, Kodak Writable CDs make use of an organic dye chemistry in their recording layer that is more conducive to 6X recording.

The recording layer’s composition is critical for several reasons. As a CD-Recordable disc rotates at higher and higher speeds, the writing laser has less and less time to affect the dye and form the pits. Consequently, either the recorder’s laser power must be increased to compensate for the reduced amount of time the write head spends over a given segment of dye, or the dye must be more sensitive to the laser light so that it may be altered more quickly.

The two most popular choices for organic dye used in the recording layer are phthalocyanine (a chemical patented by Mitsui Toatsu Chemicals and used in Kodak Writable CDs) and cyanine. It is generally acknowledged that phthalocyanine is a more stable dye under higher power laser light than cyanine and, therefore, technically superior for use in high-speed recorders like the PCD 600.

Of the many companies manufacturing or remarketing blank CD-Recordable discs, only three currently offer phthalocyanine-based media: Eastman Kodak, Mitsui Toatsu Chemicals/MTC America, and Verbatim. And among those three, only Kodak and Mitsui Toatsu explicitly guarantee 6X compatibility, though Verbatim is expected shortly to follow suit.

RECORDING STRATEGY

But blank disc dye chemistry is only a part of the story. What is really at the heart of the PCD 600 that makes hex speed recording possible is Kodak’s significant technological investment in recording strategy, or the physical manner in which the recorder decides to write the disc.

Two special techniques involved in the PCD 600’s recording strategy are Direct Read During Write (DRDW) and dynamic write laser power control. With DRDW, the unit monitors the reflected light returning from the disc to immediately assess the quality of the pits as they form. Reflectivity and pit length are intelligently examined in real-time and the unit dynamically changes the power of the write laser if it encounters dust, fingerprints, or inconsistencies in the organic dye layer. Other CD-Recorders, by and large, only calibrate the intensity of their write laser at the beginning of the recording cycle and maintain that energy level throughout the entire process, or — in some cases — only perform a few simple adjustments while recording.

The advantages of the PCD 600 system include its ability to compensate not only for variations between different discs, but also large variations within the same disc. Since the recorder is examining the results of its work, users have a great deal of assurance that the system is generating a correctly formed CD-ROM according to the physical specifications outlined in the Red and Orange Books. Discs meeting these standards are more likely to offer greater data integrity, longevity, and playback compatibility with CD-ROM drives.

THE WRITE STUFF

The obvious question is, how good a disc does all this technology produce? Quite simply, when it comes to written disc quality, the PCD 600 has no peer.

For this evaluation, tests were arranged through Enterprise Corporation International and conducted by Audio Development USA using their CD CATS SA3 Advanced test equipment. Audio Development — an acknowledged industry leader — offers disc analysis services as well as sales of commercial grade CD test equipment.

Five each of Kodak, Mitsui Toatsu, Verbatim, TDK, Ricoh, and Taiyo Yuden 74 minute discs were written and examined for compliance with Red and Orange book standards established for the full range of criteria such as jitter and deviation, push pull, BLER (Block Error Rate), E32 uncorrectable errors, reflectivity, symmetry, and the like. Of the six brands recorded, Kodak media produced the best results and the phthalocyanine-based Kodak, Mitsui Toatsu, and Verbatim discs clearly outperformed the cyanine-based Ricoh, TDK, and Taiyo Yuden media.

The most compelling fact revealed by this testing is that Kodak discs recorded with the PCD 600 at hex speed are at the very least as good, or significantly better than discs written by any other brand or model of CD-Recorder at any speed (1X, 2X or 4X). Given such solid results and the predictably high final quality of all Kodak discs written with the CD-Recorder, the PCD 600 can be relied upon for high volume service bureaus, replicators, or anyone else doing extensive data distribution or long term archiving.

The PCD Writer 600 and Disc Transporter occupy an elite position in the CD-R marketplace. Kodak’s nearest competition comes from Sony, Alea, and MicroTech Conversion Systems who chain together either double speed Sony CDW-900E or quad speed Yamaha CDR-100 recorders to write multiple discs from a single source.

These less expensive alternatives may produce maximum throughput many times faster than the PCD 600, but not with the flexibility and quality demanded by many intensive applications. No recording system other than Kodak’s is designed to run hundreds of discs at a time, day after day; produce unmatched quality CD-ROMs; operate in an unattended lights-out arrangement; or integrate as efficiently into a large network environment.

If Kodak ever decided to mass produce these units and bring costs down for reasonable consideration, the rest of the industry would indeed have something to worry about.

Author’s Note: I wish to thank the following companies for providing the various products and services used during my review of the Kodak PCD Writer 600 and Disc Transporter: Verbatim Corporation, Audio Development USA, Inc., Enterprise Corporation International, MTC America/ Mitsui Toatsu Chemicals, Inc., Taiyo Yuden (USA), Inc., TDK Electronics Corporation, Ricoh Corporation, Elektroson USA, Revelation Products Corporation, Young Minds, Inc., 21st Century Media Inc., Smart Storage Inc., OptImage Interactive Services Company, and Dataware Technologies, Inc.

Companies Mentioned in This Article

Alea Systems Inc.

(Represented in North America by)

Revelation Products Corporation

1220 Valley Forge Road

P.O. Box 2225

Valley Forge, PA 19482-2225

800/836-1823; 610/933-5875

Fax 610/933-6190

Astarte GmbH

Weberstra¤w 1

D-76133 Karlsruhe

Germany

49-(0)721-98 55 40

Fax 49-(0)721-85 38 62

Audio Development USA, Inc.

5335 Merle Hay Road, Suite 9

Johnston, IA 50131

800/444-5922; 515/254-9494

Fax 515/254-0733

Dataware Technologies, Inc.

222 Third Street, Suite 3300

Cambridge, MA 02142

617/621-0820

Fax 617/621-0307

Elektroson USA

10 Presidential Boulevard

Suite 125

Bala Cynwyd, PA 19004

800/606-6116

610/617-0850

Fax 610/617-0835

Enterprise Corporation International

1200 Valley West Drive

Suite 120

West Des Moines, IA 50266

515/223-1290

Fax 515/223-7749

Mitsui Toatsu/MTC America, Inc.

140 E. 45th Street

New York, NY 10017

800/MTC-CDRS

212/867-6330

Fax 212/867-6315

OptImage Interactive Services Company

1501 50th Street, Suite 100

West Des Moines, IA 50266-5961

800/CDI-5484; 515/225-7000

Fax 515/225-0252

Ricoh Corporation

Peripheral Products Division

3001 Orchard Parkway

San Jose, CA 95134-2088

800/955-3453

Fax 408/432-9266

Rimàge Corporation

7725 Washington Avenue South

Minneapolis, MN 55439

800/445-8288; 612/944-8144

Fax 612/944-7808

Smart Storage Inc.

100 Burtt Road

Andover, MA 01810

508/623-3300

Fax 508/623-3310

Sony Electronics Inc.

Computer Peripheral Products Company

3300 Zanker Road

San Jose, CA 95134

408/432-0190

Fax 408/943-0740

Taiyo Yuden (USA), Inc.

714 West Algonquin Road

Arlington Heights, IL 60005

800/348-2496; 708/364-6104

Fax 708/870-7828

TDK Electronics Corporation

12 Harbor Park Drive

Port Washington, NY 11050

800/835-8273

Verbatim Corporation

1200 W.T. Harris Boulevard

Charlotte, NC 28262

800/759-3475; 704/547-6500

Fax 704/547-6609

Yamaha Systems Technology

100 Century Center Court

San Jose, CA 95112

800/543-7457; 408/467-2300

Fax 408/437-9791

Young Minds, Inc.

1910 Orange Tree Lane

P.O. Box 6910

Redlands, CA 92375-0910

800/YMI-4YMI; 909/335-1350

Fax 909/798-0488

About the Author

Hugh Bennett, editor-in-chief of Hugh’s News, is president of Forget Me Not Information Systems, a reseller, systems integrator and industry consultant based in London, Ontario, Canada. Hugh is author of The Authoritative Blu-ray Disc (BD) FAQ and The Authoritative HD DVD FAQ, available on Hugh’s News, as well as Understanding Recordable & Rewritable DVD and Understanding CD-R & CD-RW, published by the Optical Storage Technology Association (OSTA).

Copyright © Online Inc. / Hugh Bennett