Isn’t it amazing that for all of the careful design they put into CD and DVD technology, the engineers never stopped to consider how discs might be labeled on the desktop? Thankfully, the marketplace has come to the rescue with its own solutions—some good, some not so good, but all ingenious in their own regard.

Our Discs Are Sealed

Hugh Bennett

EMedia: The Digital Studio Magazine, December 2003

Isn’t it amazing that for all of the careful design they put into CD and DVD technology, the engineers never stopped to consider how discs might be labeled on the desktop? Thankfully, the marketplace has come to the rescue with its own solutions—some good, some not so good, but all ingenious in their own regard.

Adhesive labels occupy one end of the spectrum, and multipurpose and specialized devices that print directly onto the disc surface occupy the other end. Convenience, cost, speed, durability, and the appearance of the result distinguish each alternative.

Labeling technologies have improved tremendously over the years and are now to the point where affordable options abound for producing good-looking, robust discs to suit most applications and environments. It is important, however, to note that manufacturers warn that some labeling techniques may impact disc performance and longevity or even compromise recording and reading drives. Since any labeling modifies a disc from its original factory-specification media and drive manufacturers often shy away from responsibility for any consequences and may even warn against certain practices (for example, Ford recommends against using discs with adhesive labels in its CD players). Such cautions may reflect legitimate concerns regarding unpredictable quality, possible transference error, and application unsuitability or simply lack of investigation into the technology. Overcautious or not, warranties may be affected, so it is prudent to follow manufacturer instructions and to use only products from reputable sources.

Over The Top: Adhesive Labels

Over The Top: Adhesive Labels

Sometimes frowned upon by the technical community, adhesive labels for CDs and DVDs enjoy an ever-increasing popularity and respectability thanks to advances in construction, versatility, appearance, and physical application. At the same time, greater competition, broad distribution, and big brand name promotion are reaching out to the masses. Among those now marketing these products are powerhouses Avery Dennison and Fellowes/Neato, media vendors Verbatim, Imation, and Memorex, and commercial provider Kyso.

In terms of their basic layout, adhesive disc labels have evolved from troublesome wedges and half-moons to round doughnut-style designs (sometimes with separate hub stickers) and now to full-face products with the same printable area as is found on commercially produced DVDs. Even eccentric business card and 80mm mini formats are available.

Labels traditionally have suffered from a reputation for affecting disc balance and readability, not sticking properly, and even sometimes wreaking havoc with drives and players. Hank Emmons, a consultant for Kyso, stresses that while these are justifiable concerns, technology has come a long way in addressing them. “The first company to put out labels used a rubber-based adhesive that could not stand up to the heat and high-speed rotation inside a drive,” according to Emmons, “but these issues have been solved.” And beyond the labels themselves, disc manufacturers contributed to problems by using troublesome silkscreen inks. For example, according to Mark Mannon, senior product manager with Avery, “Silicone does not work with adhesives, but our latest survey of available media shows that it’s no longer present in the market.”

Recently, improved tools have been introduced to apply labels so that they are better centered and smooth. Most gadgets now are variants of a flat base incorporating a spring-loaded plunger. In its upscale Afterburner kits, Avery takes the flashiest approach by using a compressible plastic saddle and labels employing detachable tabs to keep fingers away from the adhesive surface and to provide alignment points. And for high volumes, Kyso’s VS-450 fully automated labeler applies up to 1,600 labels per hour.

Recently, improved tools have been introduced to apply labels so that they are better centered and smooth. Most gadgets now are variants of a flat base incorporating a spring-loaded plunger. In its upscale Afterburner kits, Avery takes the flashiest approach by using a compressible plastic saddle and labels employing detachable tabs to keep fingers away from the adhesive surface and to provide alignment points. And for high volumes, Kyso’s VS-450 fully automated labeler applies up to 1,600 labels per hour.

Various disc decorating requirements demand that labels be available with a wide range of surfaces to accept output from all manner of devices, including color lasers, inkjet printers, and resin-based solid ink systems. White matte labels are the most affordable and (depending upon the vendor) come in both universal versions and other varieties optimized for use in particular types of printers. For the more image-conscious, gloss surfaces are also available. Inkjet printers, designed as they are to work with paper stock, have come a long way in recent years. It is not surprising, therefore, that glossy labels produced by the latest top-end models can achieve the best-looking print results of any technology.

Beyond simple background canvases, adhesive labels themselves can often steal the show. For example, Avery, Fellowes/ Neato, and Memorex offer specialized products with eye-catching finishes, including transparencies, metal foils, and holographic patterns, while Imation promotes the fashionably irradiated look of its glow-in-the-dark offerings and Verbatim markets labels mimicking the appearance of vinyl records.

Basic matte white labels are the least pricey and range from 10 cents each in high volume to 45 cents in small quantities. At between 30 cents to $1.15, photo-quality inkjet label costs reflect greater manufacturing expense (with enhanced sales margins) while holographic selections carry the premium price of $1-$1.28 each.

Still To Be Neat: Inkjet Printers

A little over ten years ago, inkjet technology was first harnessed to print directly onto the surface of CD-R discs. The first truly practical desktop labelers, inkjet printers have since been widely adopted and celebrated for their low equipment cost as well as impressive color-imaging capabilities.

Historically, all inkjet disc labelers were simply off-the-shelf consumer or office paper printers modified by third parties to physically accept discs. In adapting mass-market units, manufacturers keep hardware costs low and print quality improving by sharing in the massive research and development efforts of others. More recently, several leading inkjet printer manufacturers have themselves either openly entered the disc market or are now actively assisting others in the development of CD/DVD-capable devices. This growing list of companies now includes Primera Technology, Rimage, Microboards, Verity Systems, and luminaries Epson America and Hewlett-Packard.

These units require using specially coated “inkjet-printable” discs to work their magic. Compatible CD-R media is now offered by most brands including Verbatim, Memorex, and Imation, as well as commercial names such as Taiyo Yuden and MBI/Glyphics. DVD±R printable discs, on the other hand, are still difficult to source. Typically coming with silver and white surfaces, discs with attention-grabbing finishes are also starting to appear, including Verbatim’s Digital Vinyl CD-Rs (which look like 45 RPM records), as well as hub-coated alternatives.

These units require using specially coated “inkjet-printable” discs to work their magic. Compatible CD-R media is now offered by most brands including Verbatim, Memorex, and Imation, as well as commercial names such as Taiyo Yuden and MBI/Glyphics. DVD±R printable discs, on the other hand, are still difficult to source. Typically coming with silver and white surfaces, discs with attention-grabbing finishes are also starting to appear, including Verbatim’s Digital Vinyl CD-Rs (which look like 45 RPM records), as well as hub-coated alternatives.

Basic device design has not changed much in recent years, with units employing either manual caddy or mechanized trays to be hand fed or attached to automated labeling, duplication, and publishing systems. Depending upon the unit and resolution, throughput now varies from one to four minutes per full-surface disc. Technical underpinnings range from 1200 to 5760dpi, 3- to 6-color palettes, and 2- to 18-picoliter droplet sizes. Operating costs run anywhere from 20 to 50 cents to print a full-surface disc.

Although the onslaught of engines with more and more impressive specifications continues for paper and photo applications, some disc-labeling companies maintain that these are a mixed blessing for them. For example, faster operation and additional colors are obviously meaningful for most tasks as they enhance image quality and increase throughput. However, “droplet size is irrelevant” according to Primera vice president of sales and marketing Mark Strobel. “Everyone acknowledges that you must use high-quality photo paper to make any difference, but the top of an inkjet-printable CD or DVD isn’t the same thing.” And with little impact on image quality, Strobel points out that using higher and higher resolutions just slows things down. “This seems like a giant step backward to us,” says Strobel, “especially when a full CD can be recorded in less than three minutes.”

Instead of pursuing purely technical improvements, some manufacturers are now concentrating on expanding the market for disc duplication and labeling systems. For example, Primera’s newly updated Bravo II seeks to bring automated production down to the level of just another desktop peripheral with a more accessible price, smaller size, and friendlier disposition.

Instead of pursuing purely technical improvements, some manufacturers are now concentrating on expanding the market for disc duplication and labeling systems. For example, Primera’s newly updated Bravo II seeks to bring automated production down to the level of just another desktop peripheral with a more accessible price, smaller size, and friendlier disposition.

And destined to take disc printing to a larger market (but not to pursue it as an end in itself) is Epson America, the first mainstream printer manufacturer to enter the fray. Its latest Stylus Photo 900 and Stylus Photo 960 (see sidebar) are multifunction units augmenting their conventional paper and digital picture output with direct CD and DVD labeling capabilities. “We’re not inclined to make a dedicated printer just for discs,” says Parker Plaisted, a product manager for Epson’s specialty photo printer group. “We’re really focused on extending paper printers to CDs. We see it as a differentiating feature.”

While Epson takes the direct approach and offers its own disc-printing products, Hewlett-Packard seems content for the moment to work behind the scenes, assisting others in developing their own devices. Over the past few years, HP’s OEM division has actively supported integration of its inkjet printers into third-party disc-labeling solutions, including Rimage’s Liberty, Microboards’ Print Factory and Verity Systems’ OptiPrinter. In addition to its technical expertise, partners are also benefiting from HP’s assistance with market research and access to its vast experience says Jim Lewis, vice president of marketing for Rimage. “HP has caused us to rethink the market and look at new opportunities.”

The idea of printing directly onto CDs and DVDs is still foreign to most people, so it’s not surprising that smaller competitors welcome the addition of big name players. Commented one privately, “Just getting the world to realize that you can actually print onto a CD-R is a big step forward, so Epson’s printers are the best advertisement possible for our products.” Despite other improvements, the nature of inkjet-printed labels themselves has remained more or less constant. While colorful, attractive, and suitable for many applications, direct inkjet printing is still not universally admired—labels have a flat appearance compared to glossy paper stock or thermal re-transfer prints, images are susceptible to moisture and humidity, can be scuffed, and may even stick when placed in form-fitting packages. However, new systems are beginning to address this.

The idea of printing directly onto CDs and DVDs is still foreign to most people, so it’s not surprising that smaller competitors welcome the addition of big name players. Commented one privately, “Just getting the world to realize that you can actually print onto a CD-R is a big step forward, so Epson’s printers are the best advertisement possible for our products.” Despite other improvements, the nature of inkjet-printed labels themselves has remained more or less constant. While colorful, attractive, and suitable for many applications, direct inkjet printing is still not universally admired—labels have a flat appearance compared to glossy paper stock or thermal re-transfer prints, images are susceptible to moisture and humidity, can be scuffed, and may even stick when placed in form-fitting packages. However, new systems are beginning to address this.

Table 1: Inkjet Printers

| Epson Stylus Photo 900 | Epson Photo Stylus 960 | Rimage Liberty | Primera Signature IV | Primera SignaturePro | Primera Bravo II AutoPrinter | Microboards Disc Factory | Verity OptiPrinter | |

| Engine Manufacturer | Epson | Epson | HP | Lexmark | Lexmark | Lexmark | HP | HP |

| Cartridges/Ribbons | 2 | 7 | 2 | 1 | 2 | 2 | 2 | 2 |

| Resolution | 5760x 720dpi |

2880x 1440dpi |

4800x 1200dpi |

1200x 1200dpi |

2400x 1200dpi |

4800x 1200dpi |

4800x 1200dpi |

4800x 1200dpi |

| Output Colors | CcMmYK | CcMmYK | CMYK | CMY or K | CMYK | CMYK | CMYK | CMYK |

| Ink Droplet Size (picoliters) | 4 | 2 | 4 | 18 | 7 | 7 | 4 | 4 |

| Interface | USB, Parallel | USB, Parallel | USB | Parallel | Parallel | USB | USB, Parallel | USB, Parallel |

| OS Support | Windows, Mac OS | Windows, Mac OS | Windows | Windows | Windows | Windows, Mac OS | Windows | Windows |

| Automated | No | No | Optional | Optional | Optional | Yes (25 discs) | Yes (50 discs) | Optional |

| Media Support | CD/DVD, paper | CD/DVD, paper | CD/DVD | CD/DVD | CD/DVD | CD/DVD | CD/DVD | CD/DVD |

| Card Disc Support | No | No | No | Optional | Optional | Optional | No | Optional |

| 80mm Disc Support | Yes | Yes | No | No | No | Optional | No | Optional |

| Disc-Loading Method | Manual caddy | Manual caddy | Auto tray | Auto tray | Auto tray | Auto tray | Auto gravity feed | Auto tray |

| Labeling Software | Print CD | Print CD | CD Designer | SureThing | SureThing | SureThing, Discus | SureThing | Discus |

| Price | $199 | $349 | $1,495 | $1,495 | $1,895 | $1,495 | $2,995 | $1,895 |

Our Discs Are Sealed: Inkjet Overcoating

Our Discs Are Sealed: Inkjet Overcoating

From automobiles to hardwood floors, coatings are frequently applied to enhance appearance, impart desired textures and properties, as well as to provide protection. This makes inkjet-printable discs fair game for finishing systems now available to enhance inkjet-label look and durability. Early in the game it was suggested that labels could be covered by using spray cans of acrylic materials commonly used to protect photographs and craft projects from grubby fingers. Needless to say, the idea never really caught on given the potential for misadventure—not to mention the fumes, mess, and hassle. Fortunately, there are more high-tech ways to jacket the surface of a disc than to simply use an aerosol can. For example, Verity Systems’ new Artcoater series precisely sprays an inkjet-printed disc’s surface with a liquid lacquer and then exposes it to Ultra Violet (UV) light to cure into a solid film. And never one to miss out on an opportunity to sell more consumables, Primera Technology has introduced the Accent Disc Laminator, which uses heat and pressure to transfer a clear, resin-based ink coated with adhesive from a continuous roll of polyester film (similar to overlaminating a driver’s license).

With the imperative for outside venting, ongoing cleaning, and physical maintenance, Verity’s equipment is obviously geared toward commercial duplication and printing facilities. Prices range accordingly from $4,950 for a manually operated Artcoater station to $8,995 for a 250-disc autoloading version. In contrast, the Accent carries a price of $3,495, is office-friendly, and designed for either manual operation or integration into one of Primera’s Composer (XL/Pro/MAX) automated duplication and printing systems. According to Verity, its lacquer treatment costs roughly one cent per disc to apply, with Primera quoting 10 to 25 cents depending upon the chosen film.

Improving the robustness of inkjet-printable labels may be a neat trick, but by itself, it’s hardly an alluring sales pitch to an often price-conscious market. Fortunately, in addition to providing a sealant, overcoating brings intrinsically flat-looking labels to life by conferring a beautifully smooth high-gloss finish. It’s no surprise that Primera plays up the image-enhancing benefits of its Accent. “The image quality is incredible,” says Strobel, “and the durability is a nice bonus.”

Improving the robustness of inkjet-printable labels may be a neat trick, but by itself, it’s hardly an alluring sales pitch to an often price-conscious market. Fortunately, in addition to providing a sealant, overcoating brings intrinsically flat-looking labels to life by conferring a beautifully smooth high-gloss finish. It’s no surprise that Primera plays up the image-enhancing benefits of its Accent. “The image quality is incredible,” says Strobel, “and the durability is a nice bonus.”

This emphasis on good looks transcends simply applying transparent coatings. Taking its cue from the ID card market (Primera is a spin-off of card printer manufacturer Fargo Electronics), the Accent can also apply “AuthentiCoat” film embedded with either stock or made-to-order holographic patterns. Beyond authentication and counterfeit deterrence, Strobel says holograms offer “the cool factor, especially for DVD.”

Direct To Disc: Thermal Transfer

Direct To Disc: Thermal Transfer

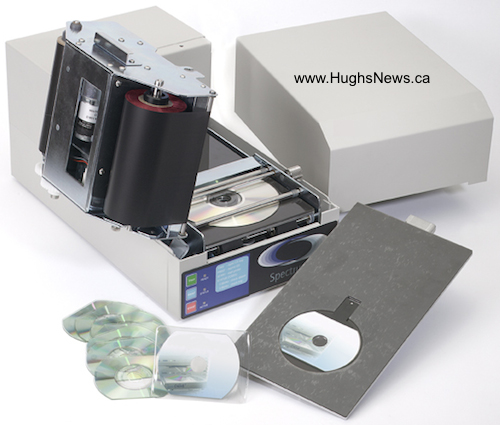

Thermal transfer technology has been a mainstay of the production and office markets since Rimage first applied it to disc labeling in 1995. And like most workhorses, it is the most unglamorous of the decorating methods with capabilities little changed over the years. Currently among the more popular units are Rimage’s PrismPlus!, Primera’s Inscripta, and MF Digital’s Spectrum2. Depending upon the printer, they typically offer indelible monochrome, two-color or CMY prints at 300 to 600dpi resolutions. Excellent for straightforward labels and spot color work, thermal transfer printers are typically prized for working on a wide range of disc surfaces and their high-speed operation (from 5 to 30 seconds per disc) and economical printing (from 3 to 35 cents per disc), making them ideal for many production applications. Units are also sometimes paired with pre-silkscreened media to provide both image quality and customization.

Table 2: Thermal Transfer and (*)Thermal Re-Transfer Printers

| Casio CW-50 | Primera Inscripta | MF Digital Spectrum2 | Rimage PrismPlus! | Rimage Everest II* | |

| Engine Manufacturer | Casio | Lexmark | CopyPro | Rimage | ALPS/Rimage |

| Cartridges/Ribbons | 1 | 1 | 1 | 1 | 2 |

| Resolution | 200dpi | 610x300dpi | 600x300dpi | 600x300dpi | 173lpi |

| Output Colors | Mono | Mono, 2-color | Mono | Mono, CMY | Mono, CMY, CMYW |

| Interface | USB | Parallel | Parallel | USB, Parallel | USB |

| OS Support | Windows | Windows | Windows | Windows | Windows, Mac OS |

| Automated | No | Optional | Optional | Optional | Optional |

| Media Support | CD/DVD | CD/DVD | CD/DVD | CD/DVD | CD/DVD |

| Card Disc Support | No | No | Optional | Optional | Optional |

| 80mm Disc Support | No | No | Optional | Optional | Optional |

| Disc-loading Method | Manual tray | Auto tray | Auto tray | Auto tray | Auto tray |

| Labeling Software | Disc Title Printer | SureThing | Spectrum2 Designer | CD Designer | CD Designer |

| Price | $129.95 | $2,995 | $3,295 | $3,995 | $5,995 |

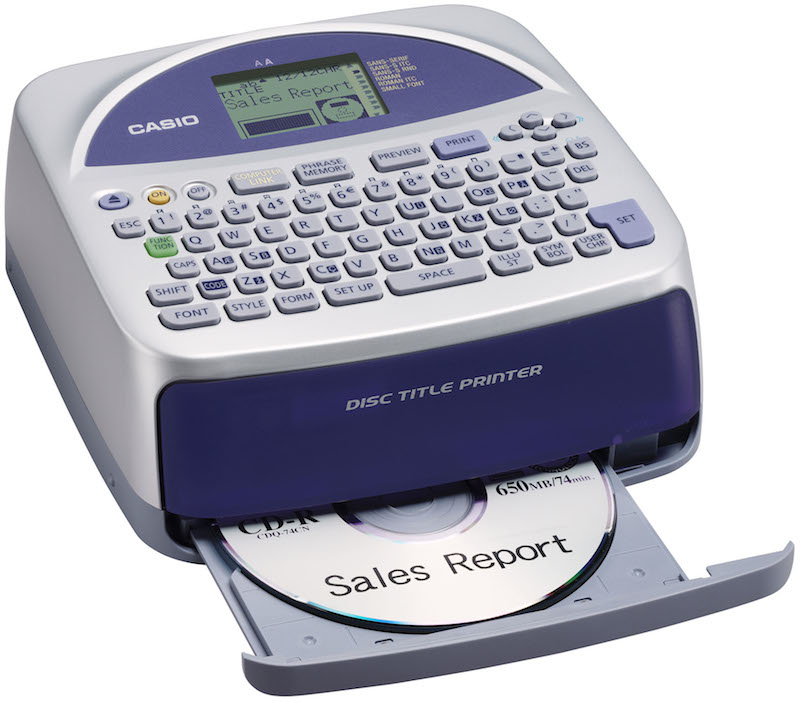

Against this somewhat mundane backdrop, Casio Computer (known for its simple and inexpensive tag and label printers) is now spicing things up by applying its expertise to make personal CD and DVD disc titling devices. Instead of taking the multifunctional inkjet path favored by Epson, Casio opts for a specialized thermal transfer approach with its new CW-50 CD-R Title Printer. At $129 and not much larger than the discs it decorates, the financially and physically diminutive CW-50 is not a full-surface labeler. Rather, the unit uses its horizontally moving print head to lay down a 200dpi monochrome swath (black, blue, red, green, or silver) roughly 2-15/16″ long and 5/8″ wide to a stationary disc. Since turnabout is fair play, discs can be manually spun 180 degrees to print on both their top and bottom. For good measure, Casio has updated this design with its latest $149 CW-75 model incorporating a small keyboard and battery pack for standalone use.

Against this somewhat mundane backdrop, Casio Computer (known for its simple and inexpensive tag and label printers) is now spicing things up by applying its expertise to make personal CD and DVD disc titling devices. Instead of taking the multifunctional inkjet path favored by Epson, Casio opts for a specialized thermal transfer approach with its new CW-50 CD-R Title Printer. At $129 and not much larger than the discs it decorates, the financially and physically diminutive CW-50 is not a full-surface labeler. Rather, the unit uses its horizontally moving print head to lay down a 200dpi monochrome swath (black, blue, red, green, or silver) roughly 2-15/16″ long and 5/8″ wide to a stationary disc. Since turnabout is fair play, discs can be manually spun 180 degrees to print on both their top and bottom. For good measure, Casio has updated this design with its latest $149 CW-75 model incorporating a small keyboard and battery pack for standalone use.

At as much as 50 cents per printed disc with basic image quality, limited printing area, and competition from adhesive labels and multi-purpose inkjets, the attraction of Casio’s offerings may not be obvious. However, the general office and consumer disc-labeling markets are hardly mature and have only re cently begun to seek options more refined than handwriting. With a recognizable brand name and broad distribution channel as well as label permanence, portability, sheer novelty, and impulse/ gift pricing, the CW-50 and CW-75 cannot easily be dismissed.

Launched A Thousand Ships: Thermal Re-Transfer

Until Rimage’s Everest appeared a few years ago, there was no easy way to create highly durable photorealistic CD or DVD labels using desktop equipment. Since then, the Everest has found its high-end home and pushed CD and DVD disc production into new frontline application areas. The Everest employs thermal re-transfer technology, the first entirely new printing method to be applied to disc labeling in years. Innovative in many regards, it produces highly durable and glossy images in monochrome/grayscale and CMY or CMYW offset quality, and optionally allows labels to cover the entire disc surface by printing over the hub-clamping area (using specially coated media).

Recently, Rimage upgraded these capabilities in its second-generation Everest II with increased output speed, enhanced resolution (from 160 to 173lpi), improved light and solid color results, and more consistent edge-to-edge printing. Responding to market pressures, Rimage has also lowered the price of its consumables (from 46 to 33 cents per CMY print), making the Everest II far more cost-effective to operate and comparable to inkjet output. But still it is very picky about what media it will accept.

However, high capital cost still separates the Everest II from the inkjet crowd with prices starting at $5,995 for the standalone unit. Also available are an upscale autoprinting version and full-blown CD and DVD production systems (Amigo/ Protégé/Autostar/Endeavor). Market observers are carefully watching to see if newly released overlaminating systems (such as Primera’s Accent) will allow inkjet to cut into markets where the Everest is now making headway.

Dilemmas No More

From adhesive labels, inkjet printers, and overcoating systems to thermal transfer and re-transfer devices, there is now a desktop thingamajig or doohickey available to satisfy nearly all discerning tastes and handle most disc-labeling chores. Today, the dilemma is not so much where to find a cost-effective and reliable solution as which one to choose.

Of course, there is always room for technical improvement, and who wouldn’t want more affordable products? High hopes rest with industry innovators Primera and Rimage and now especially newcomers Epson, Hewlett-Packard, and Casio to advance the state of the art and reach new markets.

Epson Styles Photo 960

Epson Styles Photo 960

An attractive first offering, Epson America’s new Stylus Photo 960 combines conventional paper and high-quality digital photo output with the ability to apply labels directly onto the surface of inkjet-printable writable CD and DVD discs.

At $349 and featuring high-quality imaging capabilities, the Stylus Photo 960 is considerably more expensive and sophisticated than the average home or office inkjet (paper) printer. Eye-popping image quality is achieved through 2880x1440dpi resolution (1440dpi only on CD/DVDs), six colors, and two-picoliter droplet size onto a wide assortment of cut and roll stock, including plain and coated papers, cards (up to 1.3mm thick), iron-on transfers, stickers, transparencies, and envelopes—not to mention CDs and DVDs.

Both Windows and Mac OS systems are supported through Epson’s own included Film Factory photo and CD Print disc-labeling software. During testing, CD Print proved easy to use, but ultimately disappointed, as it provides only the essentials needed to fashion rudimentary labels. Given the printer’s upscale market, Epson should take better notice of its adhesive label kit-software competition, who offer reams of background images, clip art, jewel case layouts, template wizards, and a host of other attractions.

Similar to how the Stylus Photo 960 deals with thick stock, CDs and DVDs are loaded one at a time into the front of the unit using a manual sheet-feeder attachment. To overcome the awkwardness of working with a round object, a removable rectangular plastic caddy containing a shallow circular well is used to hold the disc in proper position. Compared to similar third-party attempts to modify paper printers for disc labeling, Epson’s implementation is a cut above in both quality and execution. However, it is still possible to push the caddy in on an angle and there is enough play in the system to make precise and repeatable image alignment frustrating and virtually unattainable.

When it comes to paper-printing quality, the Stylus Photo 960 thoroughly impresses. During testing, high-resolution digital photos and scans were beautifully rendered on a variety of inkjet photo papers in excellent detail with faithfully reproduced colors and skin tones. Results from a selection of Verbatim, Memorex, and Taiyo Yuden inkjet-printable CDs were more mixed. To minimize surface wetness, the unit conservatively uses as little ink as possible so disc labels, while otherwise smart and fast drying, looked somewhat washed out.

Photo printers aren’t typically known for their swiftness, but the Stylus Photo 960 performed respectably. At 1440dpi, the unit took 2 minutes and 35 seconds to print a full 120mm disc surface with paper operation clocking at 2 minutes and 10 seconds for a 5″ x 7″ and with an 8″ x 10″ in 3 minutes 20 seconds.

With an affordable price tag, reasonable output speed, respectable image quality, and flexible media handling, the Stylus Photo 960 is an attractive multipurpose printer worth a serious look. Strictly from a disc-labeling perspective, however, the unit isn’t functionally or technically innovative and displays all the rough edges typical of a first effort.

Companies Mentioned In This Article

Avery Dennison (www.avery.com; www.cdstomper.com)

Casio Computer (www.casio.com)

Epson America (www.epson.com)

Fellowes/Neato (www.fellowes.com; www.neato.com)

Imation Corporation (www.imation.com)

Kyso (www.kyso.com)

MBI/Glyphics Media (www.glyphicsmedia.com)

Memorex Products (www.memorex.com)

MF Digital (www.mfdigital.com)

Microboards (www.microboards.com)

Primera Technology (www.primera.com)

Rimage Corporation (www.rimage.com)

Verbatim Corporation (www.verbatim.com)

Verity Systems (www.veritysystems.com)

About the Author

Hugh Bennett, editor-in-chief of Hugh’s News, is president of Forget Me Not Information Systems, a reseller, systems integrator and industry consultant based in London, Ontario, Canada. Hugh is author of The Authoritative Blu-ray Disc (BD) FAQ and The Authoritative HD DVD FAQ, available on Hugh’s News, as well as Understanding Recordable & Rewritable DVD and Understanding CD-R & CD-RW, published by the Optical Storage Technology Association (OSTA).

Copyright © Online Inc. / Hugh Bennett